In the world of processing equipment, tumble cone blenders stand out as efficient tools for mixing dry powders and granular materials. They mix together free-flowing solids in various industries, including food, pharmaceuticals, chemicals, and powdered metals. Their gentle mixing action, uniform blending capability, and high efficiency make them invaluable for achieving consistent product quality.

Overview of Tumble Cone Blenders

Tumble cone blenders feature a distinctive double-cone or V-shaped design, creating a tumbling motion that ensures thorough material intermixing. The cone shaped vessel rotates around its axis, allowing the materials inside to tumble and mix together, resulting in a homogeneous blend. This characteristic is particularly beneficial for delicate materials susceptible to damage during mixing.

For those seeking a versatile and effective mixing solution, this equipment offers a compelling choice. Their ability to handle a wide range of materials, from delicate powders to coarse granules, makes them suitable for a variety of applications. Additionally, these blenders are available in various sizes and configurations, catering to different batch sizes and production requirements.

How Tumble Cone Blenders Work:

Tumble cone blenders operate on a simple yet effective principle of gentle tumbling and intermixing. Their unique design and rotating motion create a blending environment that ensures thorough and uniform distribution of materials.

Design:

At the heart of a tumble cone blender lies its distinctive double-cone or V-shaped configuration. This arrangement forms a chamber that houses the materials to be blended. The vessel, typically constructed from stainless steel or carbon steel, is mounted on a rotating frame, allowing it to tumble freely.

Mixing Process:

As the blender rotates, the materials inside are subjected to a gentle tumbling and material folding/overlapping action. This motion causes the particles to cascade and intermix, effectively distributing them throughout the blender. The cascading effect ensures that all particles are exposed to the mixing action, eliminating segregation and promoting uniform blending.

Several factors influence the mixing time required to achieve a homogeneous blend. Material properties, such as particle size, density, and shape, play a significant role. The fill level of the blender also affects mixing time, as a higher fill level increases the frequency of particle interactions. Additionally, the speed of the blender rotation can be adjusted to optimize mixing time for different materials and batch sizes.

Discharge:

Once the desired level of blending is achieved, the blended materials are efficiently discharged from the blender. They typically incorporate one or more discharge valves strategically positioned at the base of the vessel. These valves, which can be manual or pneumatic, allow for controlled and complete removal of the blended material.

The discharge mechanism is designed to maintain the uniformity of the blend, preventing segregation or separation of components during the discharge process. This ensures that the blended product remains consistent from the first batch to the last.

Industries Suitable for Tumble Cone Blenders

Tumble cone blenders, with their gentle mixing action, uniform blending capability, and high efficiency, have found widespread application in various industries that require precise and consistent blending of dry, free-flowing solids. Let’s explore some of the key industries that benefit from the use of them:

Food Industry:

In the food industry, these blenders play a crucial role in mixing various ingredients to create consistent and flavorful products. From blending spices and seasonings to mixing dry ingredients for baked goods and cereals, cone tumble blenders ensure that each batch is uniformly blended, maintaining product quality and taste.

Pharmaceutical Industry:

In the pharmaceutical industry, where precision and consistency are paramount, they are essential for mixing pharmaceutical compounds, excipients, and active ingredients. The gentle mixing action of the blenders preserves the integrity of sensitive drugs, while their ability to achieve uniform distribution ensures that each dosage form contains the correct amount of active ingredients.

Chemical Industry:

In the chemical industry, tumble cone blenders are widely used for mixing chemicals, catalysts, and additives. Their ability to handle a wide range of materials, from fine powders to coarse granules, makes them suitable for various chemical processing applications. The uniform blending achieved by them ensures consistent product quality and safety.

Powdered Metals Industry:

In the powdered metals industry, these blenders are essential for mixing powdered metals, alloys, and other components used in the manufacture of metal parts and components. The gentle mixing action of tumble cone blenders prevents particle breakage and ensures that the blended powders are free of contaminants, maintaining the integrity and performance of the final products

Advantages of Tumble Cone Blenders

Tumble cone blenders, also known as double cone blenders or V-blenders, have gained widespread recognition for their versatility, efficiency, and ability to deliver consistently blended products. Their unique design and operating principle set them apart from other mixing methods, offering a range of benefits that make them a valuable asset in various industries.

Gentle Mixing:

Unlike more aggressive mixing methods that can damage delicate materials, these blenders employ a gentle tumbling action that preserves the integrity of the components being blended. This gentle mixing action is particularly beneficial for fragile materials such as food ingredients, pharmaceutical compounds, and powdered metals, ensuring that their properties and characteristics remain intact.

Uniform Blending:

Achieving a uniform blend is crucial for maintaining product consistency and quality. They excel in this regard, as their tumbling motion effectively distributes ingredients throughout the blender, eliminating segregation and ensuring that each batch of product is consistently blended. This uniformity is essential for meeting regulatory standards in various industries and ensuring that consumers receive products with consistent quality.

High Efficiency:

In today’s fast-paced manufacturing environment, efficiency is paramount. They are designed to optimize mixing time and energy consumption, achieving a homogeneous blend quickly and efficiently. This efficiency translates into reduced production costs, increased productivity, and a lower environmental impact. The quick mixing process also minimizes the risk of product degradation due to prolonged mixing times.

Easy Cleaning:

Maintaining a clean and hygienic working environment is essential for industries such as food, pharmaceuticals, and chemicals. These blenders are designed with ease of cleaning in mind. Their smooth, stainless steel construction and minimal internal components make them easy to sanitize and maintain, ensuring compliance with strict hygiene standards.

Versatility:

These blenders are not limited to specific materials or applications. Their versatility allows them to handle a wide range of dry, free-flowing solids, from fine powders to coarse granules. This versatility makes them a suitable choice for a variety of industries and applications, catering to different batch sizes and production requirements.

Conclusion

Tumble cone blenders, with their gentle mixing action, uniform blending capability, and high efficiency, have emerged as indispensable tools in various industries that require precise and consistent blending of dry, free-flowing solids. From ensuring the consistent taste and quality of food products to maintaining the integrity of pharmaceutical compounds and the homogeneity of powdered metals, cone tumble blenders play a pivotal role in achieving consistent product quality and safety.

Their versatility, ease of cleaning, and adaptability to a wide range of materials make them a valuable asset for manufacturers seeking to optimize their blending processes and achieve consistent results. As industries continue to strive for efficiency and precision, tumble cone blenders are poised to remain at the forefront of mixing technology, delivering consistent blends that meet the demands of today’s dynamic manufacturing landscape.

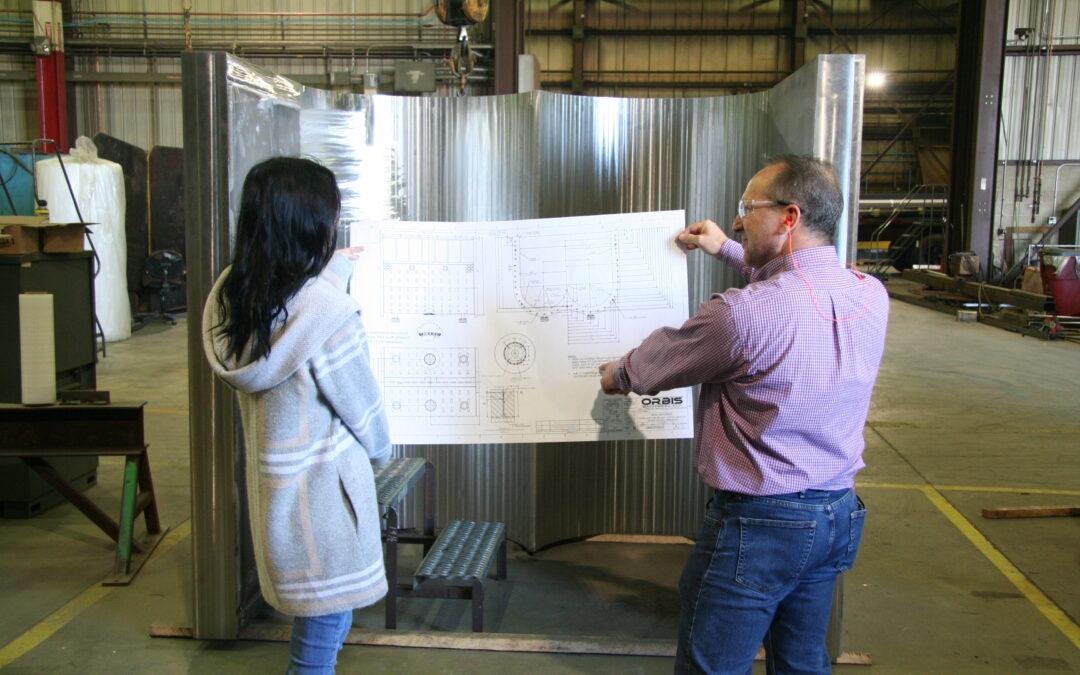

If you are considering incorporating tumble cone blenders into your production process, Orbis Machinery is your trusted partner. We are able to suit your specific needs, backed by our expertise in blending technology and commitment to customer satisfaction. Contact us today to discuss your blending requirements and discover how tumble cone blenders can elevate your production capabilities.