Featured product

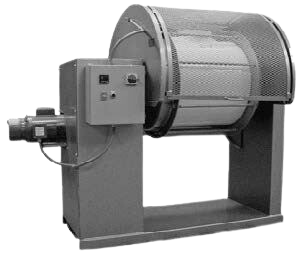

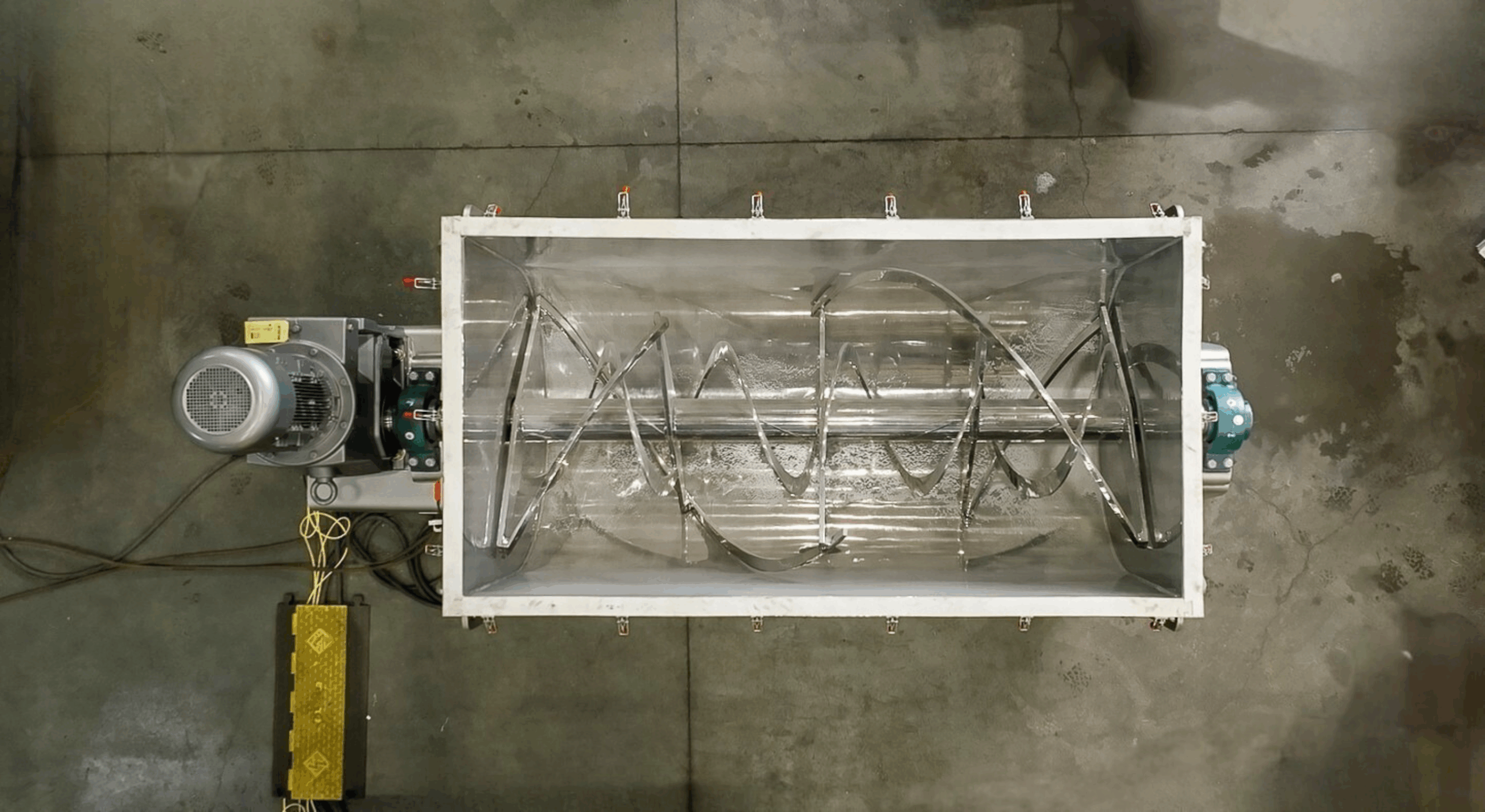

The New Orbis Machinery Adaptive Roller Mill

The Adaptive Roller Mill is designed for professionals in industries such as pharmaceuticals, cosmetics, ceramics, semiconductors, and specialty chemicals. It caters to engineers, production managers, and R&D specialists who require precise, reliable equipment for laboratory, testing, and light production applications.

- Enhanced Power

- Wide Range of Applications

- Adaptability

- Customer-Centric Design