Visit us at the upcoming 2026 Shows: Ceramics Expo Dates: May 5-6, 2026 Location: Huntington Convention Center of Cleveland, Ohio, USA Orbis Machinery Booth: # 609 Why Attend? Stay ahead with the latest advancements in composite and advanced material...

News and Events

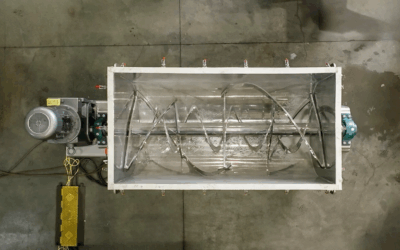

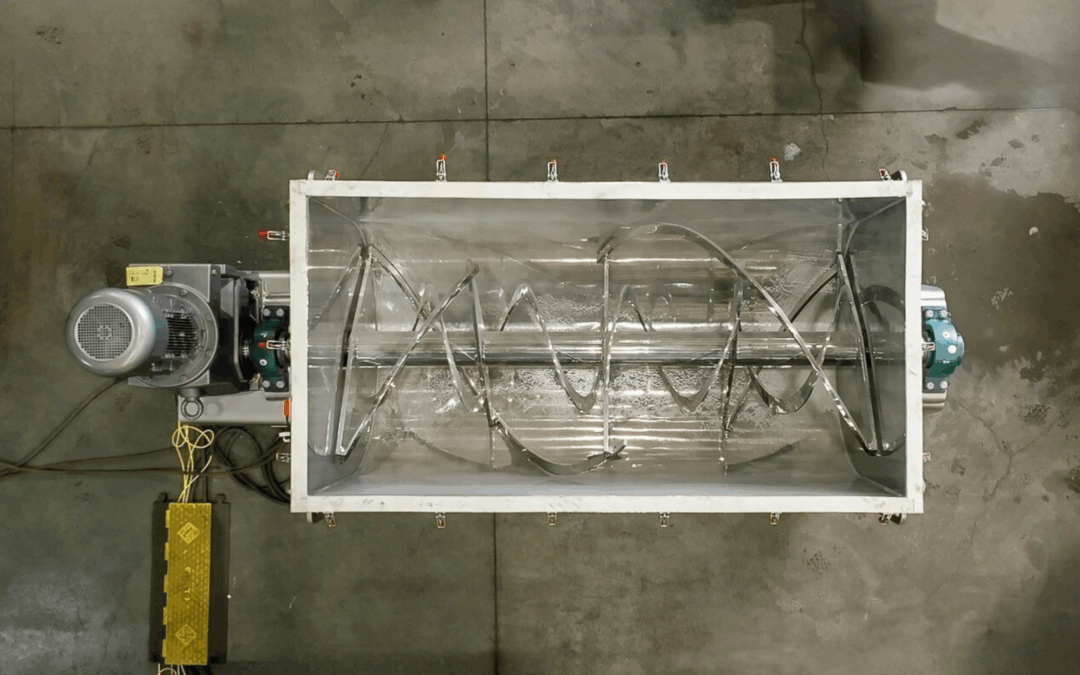

Engineering High-Viscosity Mixing for Rubber and Adhesives

Engineering Solutions for Consistency, Throughput, and Process Control High-Viscosity Mixing Is Not Just Difficult, It Is a Production Risk Rubber compounds and pressure-sensitive adhesives are some of the most stubborn, high-torque materials in manufacturing....

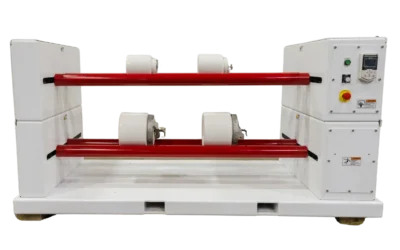

Ribbon vs. Paddle Blenders: Food Processing Efficiency

In food manufacturing, consistency is everything. From the texture of dough to the uniformity of a seasoning blend. Behind every reliable product is a dependable mixing process, and two of the most commonly used tools for achieving this are ribbon blenders and paddle...

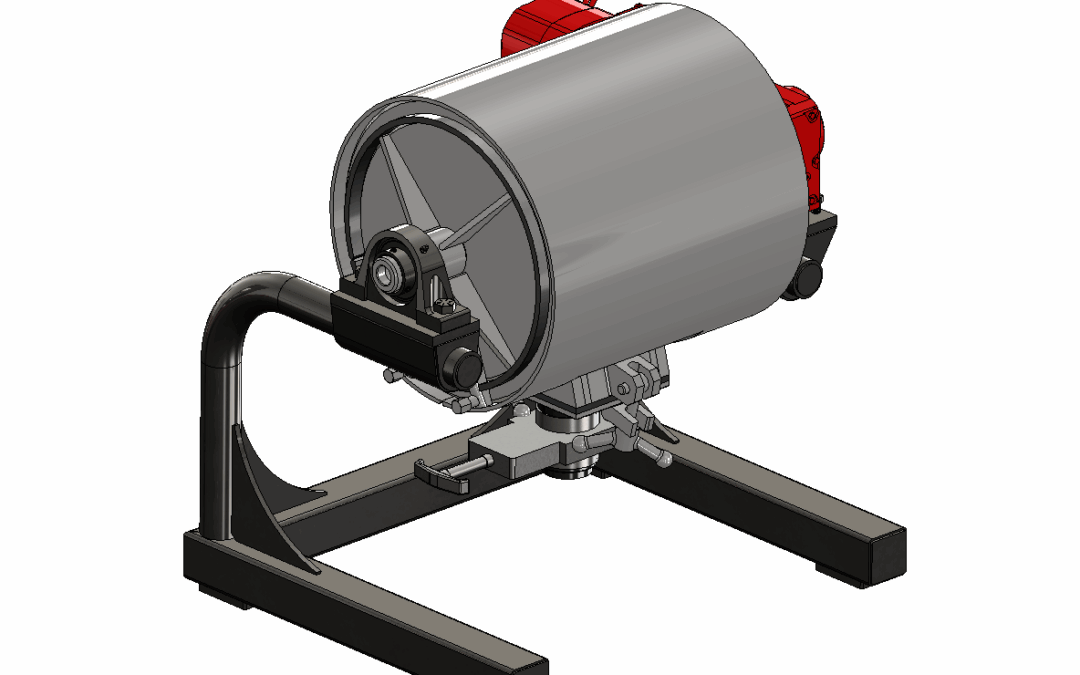

Ball Mill Scale-Up: Why Lab Testing Prevents Costly Mistakes

In industries like ceramics, chemicals, pharmaceuticals, and materials science, ball milling is a critical process for reducing particle size, enhancing material performance, and preparing inputs for downstream applications. But here’s a common trap many teams fall...

Uniform Fiber Distribution in Composites with Double Arm Mixers

Why Fiber Distribution Matters in Composite Manufacturing In composite production, material performance starts with mixing. The uniformity of fiber dispersion within the resin matrix is a critical yet often underestimated factor in determining the strength,...

Mixer Shaft Seals Explained: How to Choose

Mixer shaft sealing is crucial for preventing leaks and maintaining optimal performance in various industries like chemical, pharmaceutical, food, and wastewater treatment. Different types of sealing solutions, such as standard rope packing, AIS seal rings, and...

Low Impact Mixing for Powders, Spices and Dry Food Ingredients

In food processing, mixing fragile, dry ingredients like protein powders, spices, or nutritional supplements requires precision, not force. Cone tumble blenders offer low-impact, hygienic blending designed to protect ingredient integrity and ensure batch consistency...

Mixing Consistency in Candy Production

In industries that work with high-viscosity materials, like food, plastics, chemicals, or composites, mixing consistency is often the most critical factor in achieving product quality. A slight inconsistency in how ingredients are blended can lead to texture issues,...

Precision Milling Guide: Best Practices for the Adaptive Roller Mill

Achieving Maximum Efficiency in Your Milling Operations Achieving efficiency in milling isn't just about having the right equipment, it's about using it effectively. Without proper calibration and maintenance, even the best milling systems can lead to...

How the Adaptive Roller Mill Supports Diverse Industries

Overcoming Industry Challenges with Adaptive Milling Achieving precision milling in pharmaceuticals, specialty chemicals, and R&D labs is more challenging than ever. Inconsistent particle sizes, excessive reprocessing, and inefficiencies can slow production and...

Introducing the Adaptive Roller Mill: For R&D, Pharma & MFG

Scaling Innovation with the Right Milling Solution How do you scale precision milling in an R&D environment without investing in multiple machines? Many research labs, universities, and specialty manufacturers face this exact challenge, until now. The Adaptive...