Tumble Blending

Whatever your blending requirements, Orbis Machinery has the solution to fit your process!

Blending in its simplest form is the combining of two or more materials to produce a homogeneous mixture. Normal tumble blending of free flowing materials provides a gentle mixing action. We offer two types of tumble blenders:

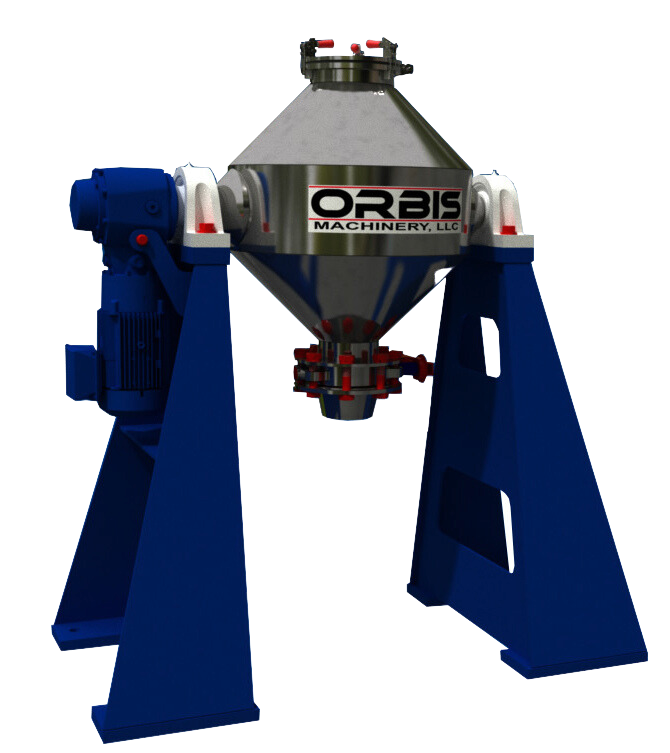

Cone Blenders

The double cone blender consists of two cones welded to a cylindrical center section that provides a gentle, low shear tumble action of the product. Cone blending also results in a high degree of particle mobility without the use of internal baffles. Cone blenders have proven successful in a wide variety of industries, offering greater overall volume and high efficiency with blend variations of 2% or less. We offer both a 45° and 60° cone version.

V-Shape Blenders

With the Orbis Machinery V-shape blender the blend is achieved by the constant rolling action of the classic tumble blender. Each leg of the V-shape shell works independently to efficiently achieve a uniform blend. This precise mixing action results in blend variations of 2% or less. Each cylindrical leg has an access cover for easy material loading and cleaning.

Standard Features

- Standard Designs for Material Densities up to 250 lbs/cf

- 0.5 to 500 Cubic Foot Working Capacities

- 304 or 316 Stainless Steel or Carbon Steel Construction

Choose Orbis Machinery for Your Blending Needs

With Orbis Machinery’s double cone blender and V-shape blender solutions, you can achieve consistent, high-quality blends for your products. Our expertise in tumble blending guarantees that you have the right equipment to optimize your blending processes.

Contact us today and explore our solutions to find the ideal fit for your production needs!

Design Options

- Operator/Control Panels

- Explosion Proof Motors & Drives

- Brake Motors

- Pneumatic Valves & Interlocks

- Safety Enclosures

- Sampling Covers

- Explosion Proof Motors

- ASME Code Stamped Jackets

- Polished Finishes

- Internal Coatings

- Containment Systems

- Indexing Systems

- Load Cells

- Exotic Alloy Contact Parts

- C.I.P. Systems

- Drum Loading Systems

- Vibrators

Models

| Model # | Working Volume (65% T) (Cu.Ft.) | Total Volume (Cu.Ft.) | Diameter (CB, in) | Rotational Speed (RPM) | HP (60 lbs/cu ft) | Hatch Dia. (in.) | Disch Dia. (in.) |

|---|---|---|---|---|---|---|---|

| CTB025-11 | 0.25 | 0.39 | 11 | 30 | 1/4 | 4 | 4 |

| CTB05-14 | 0.5 | 0.77 | 14 | 28 | 1/4 | 6 | 4 |

| CTB1-17 | 1 | 1.54 | 17 | 22 | 1/4 | 8 | 6 |

| CTB3-25 | 3 | 4.66 | 25 | 19 | 1/2 | 8 | 6 |

| CTB6-31 | 6 | 9.26 | 31 | 18 | 3/4 | 8 | 6 |

| CTB10-37 | 10 | 15.4 | 37 | 16 | 1 | 10 | 8 |

| CTB15-43 | 15 | 23.14 | 43 | 16 | 2 | 14 | 8 |

| CTB20-47 | 20 | 30.82 | 47 | 14 | 3 | 16 | 8 |

| CTB30-53 | 30 | 46.25 | 53 | 13 | 3 | 16 | 8 |

| CTB40-59 | 40 | 61.62 | 59 | 12 | 5 | 16 | 8 |

| CTB50-63 | 50 | 76.96 | 63 | 11 | 7 1/2 | 16 | 10 |

| CTB75-73 | 75 | 115.47 | 73 | 11 | 10 | 16 | 10 |

| CTB100-80 | 100 | 153.85 | 80 | 10 | 15 | 16 | 12 |

| CTB125-86 | 125 | 192.44 | 86 | 9 | 15 | 18 | 12 |

| CTB150-92 | 150 | 230.89 | 92 | 9 | 20 | 18 | 12 |

| CTB200-101 | 200 | 308.53 | 101 | 8 | 30 | 18 | 12 |

| CTB250-109 | 250 | 384.63 | 109 | 8 | 30 | 18 | 12 |

| CTB300-115 | 300 | 462.77 | 115 | 8 | 40 | 18 | 12 |

| CTB350-121 | 350 | 538.39 | 121 | 8 | 40 | 24 | 12 |

| CTB400-127 | 400 | 616.88 | 127 | 7 | 50 | 24 | 16 |