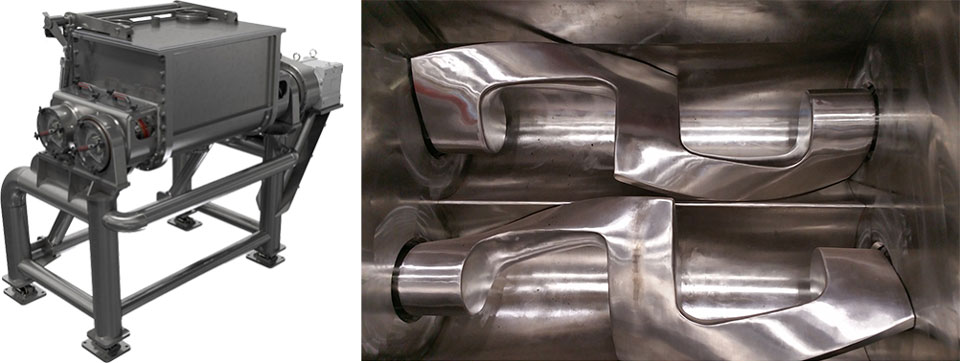

Double Arm Mixers & Mixer Extruders

Orbis Machinery custom-designs and engineers Double Arm Mixers and Mixer Extruders for shearing and kneading high viscosity products.

We offer three varieties of double arm mixers:

- Tilt Discharge

- Bottom Dump

- Auger Discharge

We can point out the benefits of each type and help you choose the proper one to best accommodate your process and product characteristics. For high viscosity material mixers, Orbis Machinery delivers just the right mix of reliability, dependability and flexibility.

Design Options

- Materials ranging from Carbon Steel Contact Parts to Exotic Alloys

- Cover Kits including Dust /Vapor Tight or Vacuum-Designed Covers

- Full Vacuum Internal Ratings

- Removable Wear Liners on all Contact Components

- Turn Key Controls

- Conventional, Dimple, Pipe Coil or Electrically-Heated Jackets

- Sigma, Dispersion, Masticator or Naben Style Blades

- Tangential, Overlapping or Naben Blade Designs

- Vacuum Systems

- Heating Systems

- Blade Coring

- High Pressure Displacement Discharge Pumps

- ASME and TUV certifications

- VF Drives

- Hydraulic Drives

- Mechanical Shaft Seals

- Food & Confection Designs

Sanitary Double Arm Mixers

Model DLK-50 Sanitary Mixer Shown. Click for additional information on Sanitary Mixers.

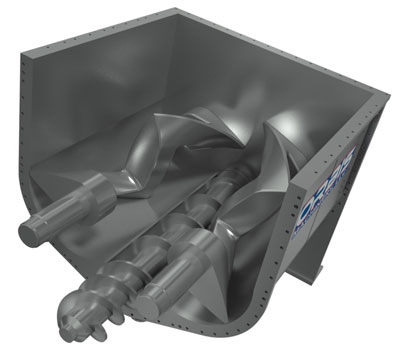

The Orbis Machinery mixer extruder incorporates the performance of a double arm mixer with the added convenience of an auger for discharging. While mixing, the auger rotates in reverse to aid in the mixing process. When the mixing cycle is complete, the auger is reversed and materials are conveyed through the discharge barrel (located in the lower section of the bowl) into a discharge die that can feed downstream equipment.

MODEL DKx1000 MIXER

Typical Applications:

- Adhesive

- Carbon

- Ceramics

- Chemical

- Confection

- Food

- Healthcare

- Nutraceutical

- Paper & Pulp

- Pigments

- Rubber

- Sealants

Standard Laboratory Models

Custom engineered designs are available in sizes from 1/4 to 1200 gallon working capacities. DKL-6 model shown.

| Model # | Total Capacity (Quart) | Working Capacity (Quart) | Bowl Length (L-R) (in) | Bowl Width (F-B) (in) | Bowl Depth (in) | HP | Overall Length | Overall Width | Overall Height | Approx WT (lbs) |

|---|---|---|---|---|---|---|---|---|---|---|

| DKL-1 | 1.5 | 1 | 4.63 | 5.75 | 5.75 | 3/4 | 31 | 24 | 36.5 | 230 |

| DKL-2 | 3.75 | 2 | 7.5 | 5.75 | 5.75 | 3/4 | 35 | 24 | 36.5 | 250 |

| DKL-3 | 4.5 | 3 | 7 | 8.5 | 8.5 | 1 | 38.4 | 27 | 29.4 | 390 |

| DKL-4 | 4.5 | 4 | 9 | 8 | 8.5 | 1.5 | 40 | 27.5 | 29.4 | 395 |

| DKL-6 | 9 | 6 | 9 | 8.5 | 8.5 | 1.5 | 40.5 | 27.5 | 29.4 | 400 |

ORBIS MACHINERY CAN CUSTOM ENGINEER ANY SIZE LABORATORY DOUBLE ARM KNEADER