Engineering Solutions for Consistency, Throughput, and Process Control

High-Viscosity Mixing Is Not Just Difficult, It Is a Production Risk

Rubber compounds and pressure-sensitive adhesives are some of the most stubborn, high-torque materials in manufacturing. They are tacky, shear-sensitive, filler-dense, and heat-reactive. They demand precise dispersion, tight temperature control, and equipment built to push through extreme viscosity resistance.

When mixing is not engineered correctly, the consequences show up fast:

- inconsistent mechanical properties

- premature scorch or thermal runaway

- additive pockets or poor filler distribution

- off-viscosity batches

- rejected product or rework

- lost production hours

- material waste

As the industry shifts toward higher filler loads, sustainable and recycled rubber blends, and tougher adhesive chemistries, the mixing challenges only grow.

This article breaks down why high-viscosity rubber and adhesive mixing fails and how engineering-driven Double Arm Mixer Extruders solve those issues with predictable, repeatable performance.

The Real Challenges Behind Rubber and PSA Mixing

1. High Filler Loads Demand True High-Shear Capability

Modern rubber and adhesive formulas increasingly rely on carbon black, silica, recycled rubber content, biobased additives, tackifiers, resins, and plasticizers. These materials drastically increase mixing difficulty.

What goes wrong:

- agglomerates remain intact

- filler distribution becomes inconsistent

- micro uniformity is lost

- downstream processes such as extrusion, calendering, molding, or coating become unpredictable

What is needed:

A shear profile that tears, folds, elongates, and compresses the material, not one that simply moves it around.

2. Temperature Control Determines Success or Failure

Rubber and adhesives both generate heat rapidly under shear.

Too much heat leads to scorch risk, polymer degradation, and premature curing. Too little heat leads to incomplete dispersion and extended cycle times. Temperature is the silent killer of batch stability.

Effective engineering solutions include:

- jacketed bowls

- optional cored blades

- controlled shear profiles

- optimized heat-transfer surfaces

- sensors and automated thermal management

When the mixer controls temperature, the operator controls product quality.

3. Mixers Must Push Through Extreme Viscosity

Rubber fights back.

PSAs fight back even harder.

Without proper torque delivery:

- cycles drag

- energy use increases

- wear accelerates

- operators intervene more

- scrap increases

Heavy-duty, torque-dominant engineering becomes essential.

4. Consistency Across Batches Is Everything

Batch-to-batch variation impacts:

- adhesion performance

- tensile strength

- curing behavior

- viscosity targets

- customer confidence

High-viscosity materials require precision shear, stable thermal curves, repeatable cycle parameters, and automated controls. Consistency is not optional. It is the requirement.

How Orbis Double Arm Mixers Solve High Viscosity Challenges

This is where the standard mixer conversation ends and the engineering conversation begins. Orbis Double Arm Mixer Extruders are engineered specifically to eliminate the failure modes that make rubber and adhesives so difficult to process.

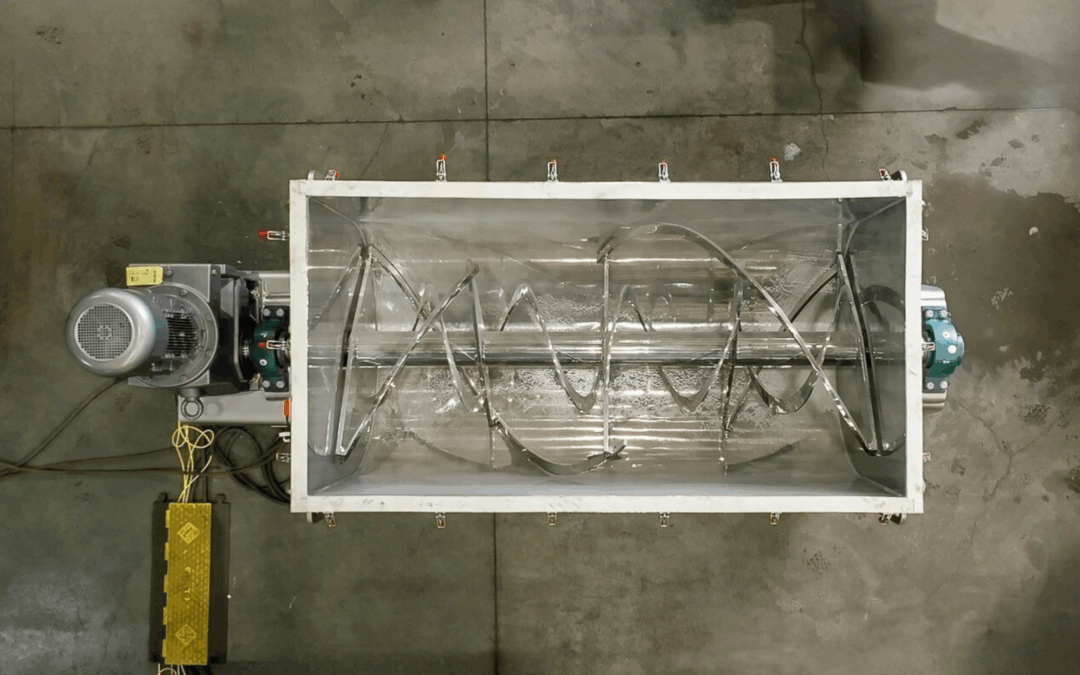

1. Counter-Rotating Blades Built for Rubber and Adhesives

Orbis blade geometry is engineered to:

- fold heavy, dense compounds

- break down filler clusters

- drive consistent shear

- move material efficiently through the bowl

- eliminate dead zones

This is the backbone of true, uniform dispersion.

2. Precision Temperature Control Built Into the Design

Orbis systems include:

- jacketed trough heating and cooling

- optional cored blades for internal thermal stability

- optimized contact surfaces

- predictable heat transfer across the batch

Result:

- tighter temperature windows

- reduced scorch risk

- better control over cure-sensitive formulations

- more predictable cycle times

Thermal stability equals material integrity.

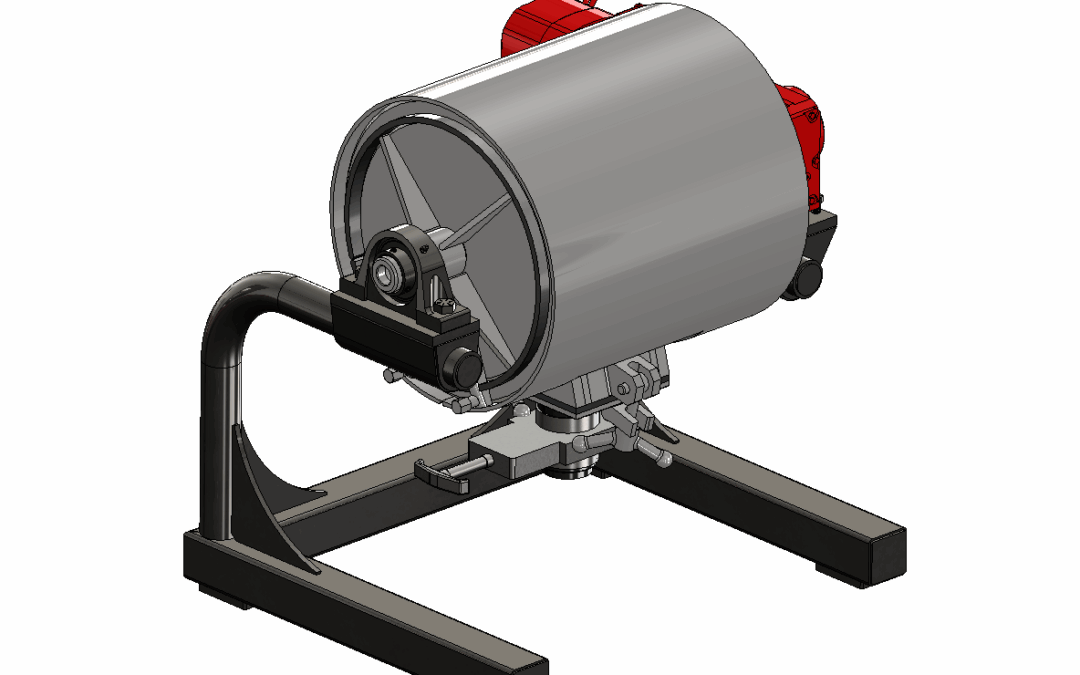

3. Multiple Discharge Options for High-Viscosity Material

Rubber and adhesives do not flow. They require engineered discharge strategies.

Orbis offers:

- tilt discharge for dense, cohesive compounds

- bottom drop discharge

- auger discharge for high-tack materials or downstream forming and extrusion

Discharge configuration must match downstream workflow, and we design it accordingly.

4. Shorter Mixing Cycles and Higher Throughput

With automation-ready controls, operators gain access to:

- torque monitoring

- temperature profiles

- cycle automation

- batch repeatability

- trend tracking

- recipe-based operation

Rubber and adhesive production thrives on predictable, automated outcomes, not operator guesswork.

Why This Matters for Fast-Growing Rubber and Adhesive Manufacturers

As formulations evolve and customer expectations rise, manufacturers need equipment that:

-

handles recycled or sustainable materials

-

disperses high filler loads reliably

-

eliminates thermal risk

-

increases throughput without compromising quality

-

reduces scrap

-

maintains tight batch consistency

-

integrates into existing process controls

This is the exact environment Orbis DAM systems are engineered for.

Industry Shifts That High-Viscosity Producers Cannot Ignore

Even the most established rubber and adhesive manufacturers are rethinking their mixing strategy because of three accelerating trends.

1. Automation and Data-Driven Mixing Control

Torque curves, temperature profiles, viscosity monitoring, and recipe control have become standard requirements. Plants need equipment that integrates into closed-loop automation and predictive analytics.

2. Sustainability and Recycled Inputs

Higher levels of recycled elastomers, bio fillers, and devulcanized rubber increase viscosity and make dispersion more difficult. Mixers must deliver higher shear without overheating.

3. Rising Quality Expectations in End-Use Markets

Automotive, aerospace, medical, electronics, and building materials all demand:

- tighter dispersion

- lower variation

- predictable cure behavior

- material purity

- consistent viscosity

Older mixer designs were not engineered for these expectations.

This context reinforces why equipment built for high-viscosity materials is no longer optional. It is the baseline for competitiveness.

Why Rubber Processors Choose Orbis for High-Viscosity Challenges

Rubber and adhesive manufacturers choose Orbis because they need equipment engineered for rubber, not equipment that simply tolerates it.

Orbis delivers:

-

high-viscosity torque capacity

-

superior shear and folding

-

controlled thermal environment

-

configurable discharge options

-

custom engineering based on formula and workflow

-

long equipment life under constant mechanical load

-

lower maintenance requirements

-

repeatable, predictable mixing results

Orbis stands apart through engineering precision built around real rubber and adhesive challenges.

If Your High-Viscosity Mixing Is Holding You Back, Your Equipment Might Be the Reason

Rubber and adhesive mixing issues are rarely random. They are symptoms of equipment that was not built for extreme viscosity, modern formulations, or today’s quality demands.

Orbis Double Arm Mixers provide:

-

the shear required for high-filler materials

-

the thermal stability needed for sensitive chemistries

-

the throughput modern processes demand

-

the consistency customers expect

If you are seeing variability, long cycle times, thermal spikes, or dispersion issues, it may be time to evaluate whether your current mixing technology can support your future production needs.