Why Fiber Distribution Matters in Composite Manufacturing

In composite production, material performance starts with mixing. The uniformity of fiber dispersion within the resin matrix is a critical yet often underestimated factor in determining the strength, reliability, and quality of the finished part.

Whether you’re producing structural components for aerospace, automotive, wind energy, or industrial applications, inconsistent fiber distribution can lead to:

● Weak zones that reduce load-bearing capacity

● Delamination or failure under dynamic stress

● Excess resin usage, increasing costs and weight

● Poor processability during molding or forming

For manufacturers striving for consistency, especially with long or high-load fibers, the mixing stage is not optional, it’s foundational.

The Mixing Challenge: Why High-Viscosity Composites Require Specialized Equipment

Composite resins filled with glass, carbon, or natural fibers can be extremely viscous and difficult to mix. Traditional mixers often fall short, either damaging the fibers or leaving them unevenly dispersed.

Common challenges include:

● Clumping or matting of fibers

● Fiber settling during batch hold times

● Inadequate shear forces to achieve full wet-out

● Incompatibility with high-viscosity or high-solids formulations

These issues not only threaten mechanical integrity but also reduce line efficiency and product consistency across batches.

What Makes Double Arm Mixers Ideal for Fiber-Filled Composites?

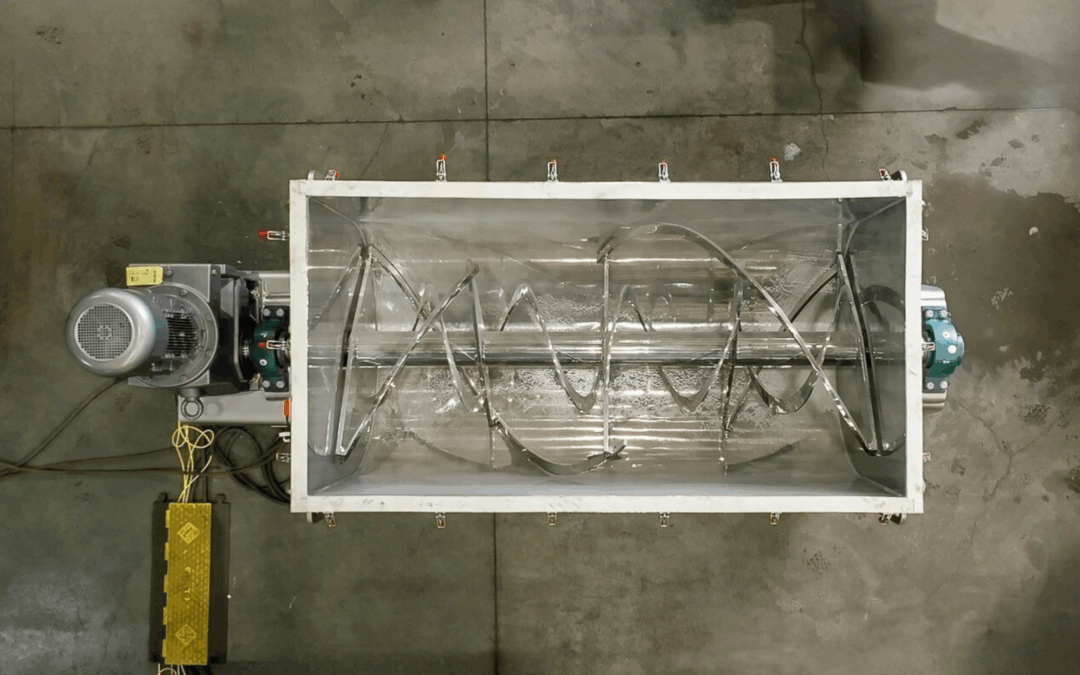

At Orbis Machinery, our Double Arm Mixers are designed specifically to address these composite processing challenges. Featuring two counter-rotating blades (sigma, dispersion, masticator or Naben), these mixers deliver superior kneading, folding, and shear, all within a controlled environment. Blade action can be configured as tangential, overlapping, or Naben, depending on your application.

Key Benefits of Double Arm Mixers for Composites:

● Uniform Fiber Dispersion: The intermeshing blades promote complete distribution without damaging fiber length or integrity.

● Scalable Consistency: From pilot-scale batches to continuous production, the same level of fiber homogeneity is maintained.

● Gentle Yet Thorough Shear: Enough force to achieve full resin wetting, without over-mixing or generating excessive heat.

● Custom Configuration: Trough geometry, discharge method, and blade shape are all engineered to your process requirements.

Fiber-Filled Composite Materials: Applications on the Rise

Industries are increasingly demanding stronger, lighter, and more sustainable materials. That’s why consistent fiber dispersion isn’t just a quality issue, it’s a competitive advantage.

Market Trends Driving Demand for Better Mixing:

● Automotive & Aerospace: Light weighting goals are pushing for stronger composite panels with long fiber reinforcement.

● Construction & Infrastructure: Pultruded and molded parts need reliable fiber/resin ratios to ensure long-term performance.

● Bio-Based Composites: Natural fibers like flax, hemp, or recycled carbon fiber are harder to disperse uniformly, raising the need for advanced mixing technology.

● Sustainability Mandates: Consistency is essential when substituting virgin materials with reclaimed or recycled inputs.

Mixing inconsistency in any of these applications can create downtime, rework, or scrap, adding costs and risking compliance with stringent industry specifications.

Why Off-the-Shelf Mixers Don’t Cut It

Most off-the-shelf mixing equipment isn’t designed for the demands of composite materials.

Generic designs often lack:

● Adequate torque or blade strength for viscous resin-fiber blends

● The control needed for heat-sensitive materials

● Configurability for evolving fiber types, viscosities, and filler loads

At Orbis, we believe your mixer should match your process, not the other way around. That’s why every Double Arm Mixer is engineered to order, based on your batch size, material rheology, throughput needs, and integration requirements.

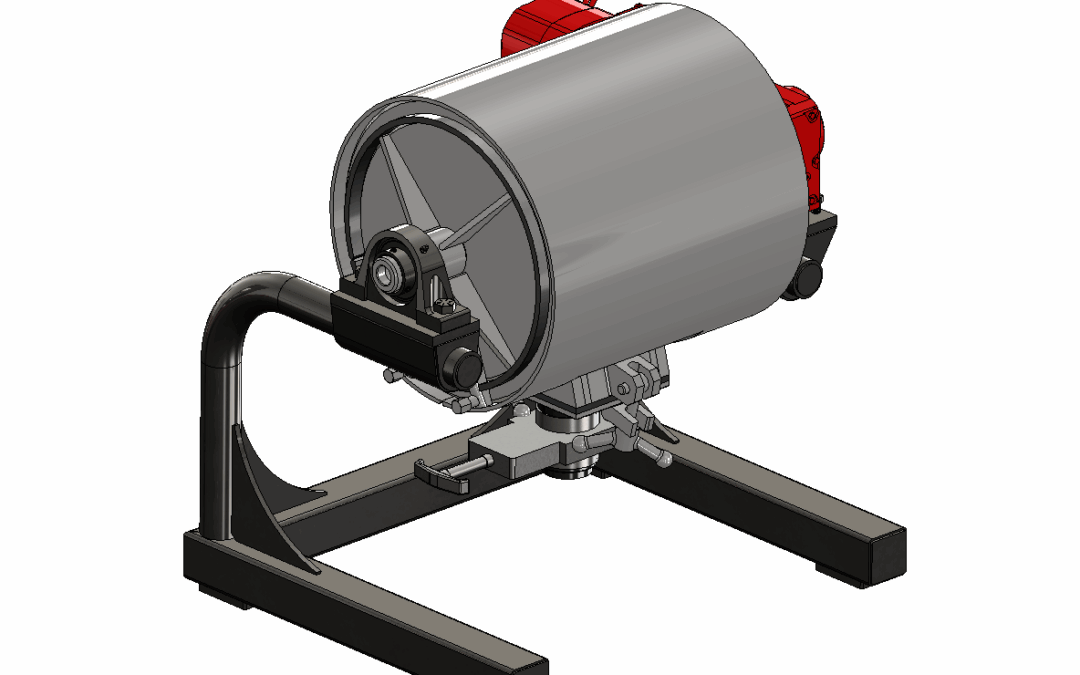

How Orbis Machinery Delivers an Engineered Mixing Solution

When you partner with Orbis, you’re not just purchasing a piece of equipment, you’re investing in a purpose-built solution backed by decades of engineering expertise.

What Sets Us Apart:

● Custom Blade Designs to balance shear and folding for delicate or aggressive mixing

● Discharge Options like bottom dump, tilt, or auger for efficient handling of fiber-rich batches

● Heat Management Integration via jacketed troughs or cooling elements

● Support from Concept to Commissioning, including consultation, CAD drawings, testing, and service

Smart Buyers Ask This: “How Do I Know It Wil Work for My Material?”

Great question. And the answer lies in our consultative approach. We work with your engineers to understand fiber types, resin viscosity, filler ratios, and thermal limitations. From there, we design a mixing system that’s tailor-made for your process.

If you’re not getting consistent results today or you’re scaling up and need more control our team can help you select or configure the right system for your facility.

Final Thoughts: Don’t Let Your Mix Limit Your Composite Performance

If you’re working with fiber-filled compounds and struggling with inconsistency, Orbis’s Double Arm Mixers offer a solution that’s both robust and customizable. Reliable fiber dispersion means better product performance, reduced waste, and fewer surprises on the production floor.