In food manufacturing, consistency is everything. From the texture of dough to the uniformity of a seasoning blend. Behind every reliable product is a dependable mixing process, and two of the most commonly used tools for achieving this are ribbon blenders and paddle blenders.

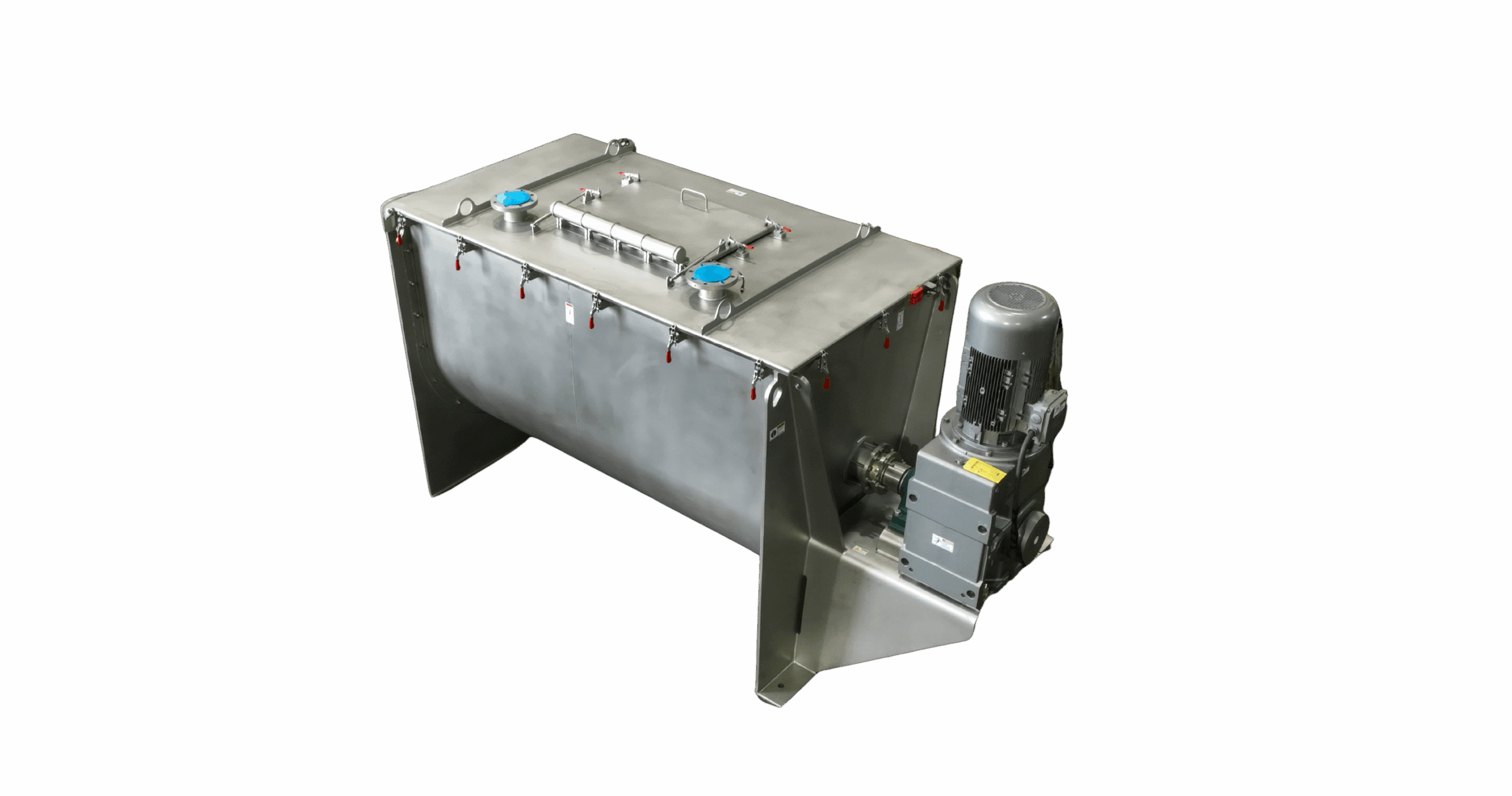

Both are versatile, efficient, and customizable, but understanding their differences can help food processors improve throughout, reduce waste, and ensure every batch meets the same high standards of quality and taste. Orbis ribbon and paddle blenders are available in working capacities up to 500 cubic feet and can be equipped with ASME code jackets for temperature controlled processing.

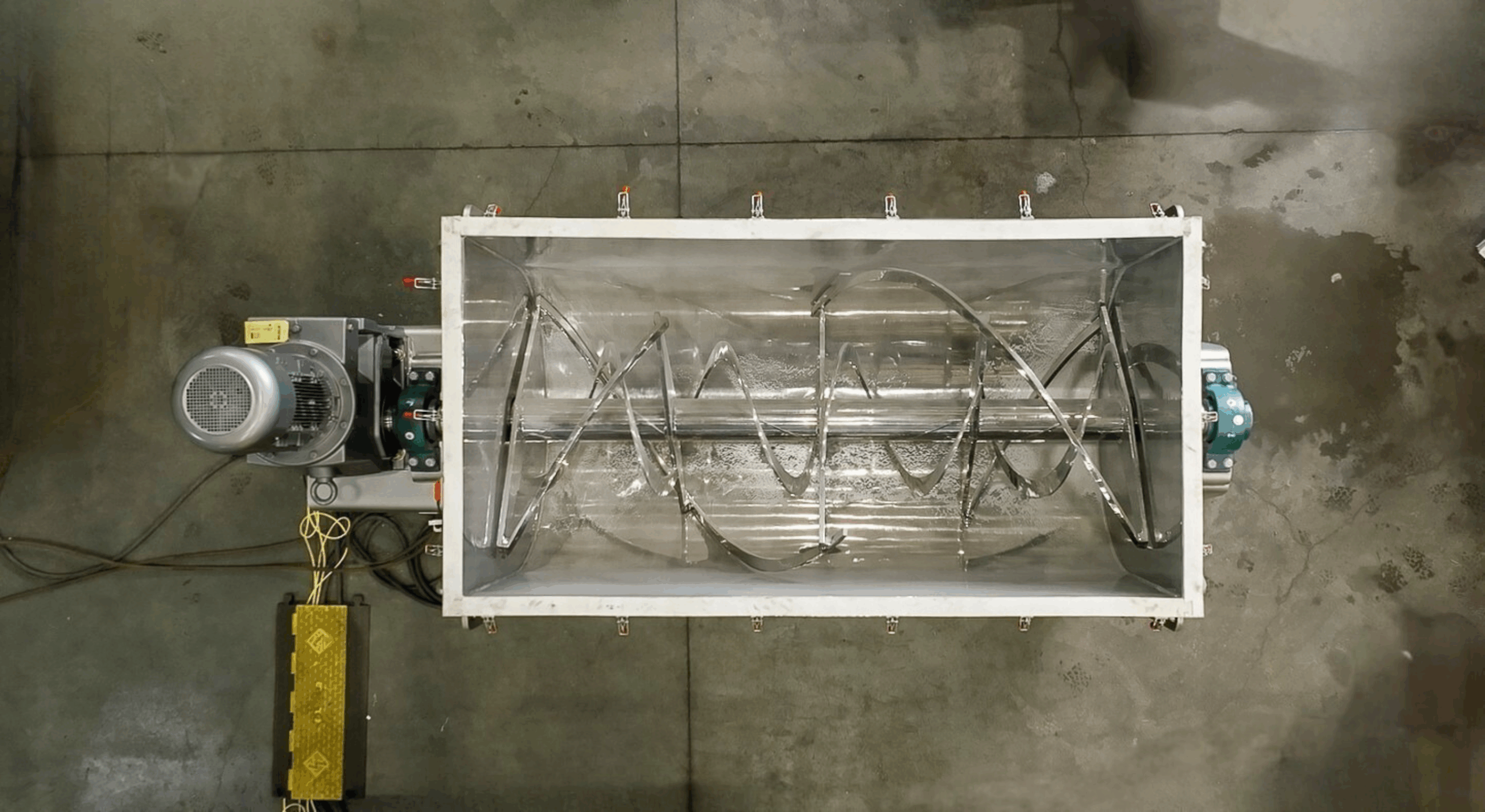

Understanding Ribbon Blenders

Ribbon blenders are horizontal mixers designed with double-helical ribbons that rotate within a U-shaped trough. The outer ribbons move ingredients in one direction while the inner ribbons move them in the opposite direction, creating a continuous flow that ensures a uniform blend.

They’re ideal for handling dry powders and free-flowing materials, making them a staple in food manufacturing environments where precision and high-volume mixing are essential.

Key Advantages of Ribbon Blenders

-

-

- Uniform Mixing: The countercurrent ribbon design ensures even distribution of ingredients, even across large batch sizes.

- High Capacity: Perfect for large-scale food production, including baking mixes, spices, and powdered beverages.

- Energy Efficient: Requires relatively low power compared to other batch mixers, helping maintain cost efficiency.

- Customizable Design: Options such as jacketed troughs for temperature control or sanitary stainless finishes can enhance food-grade performance.

-

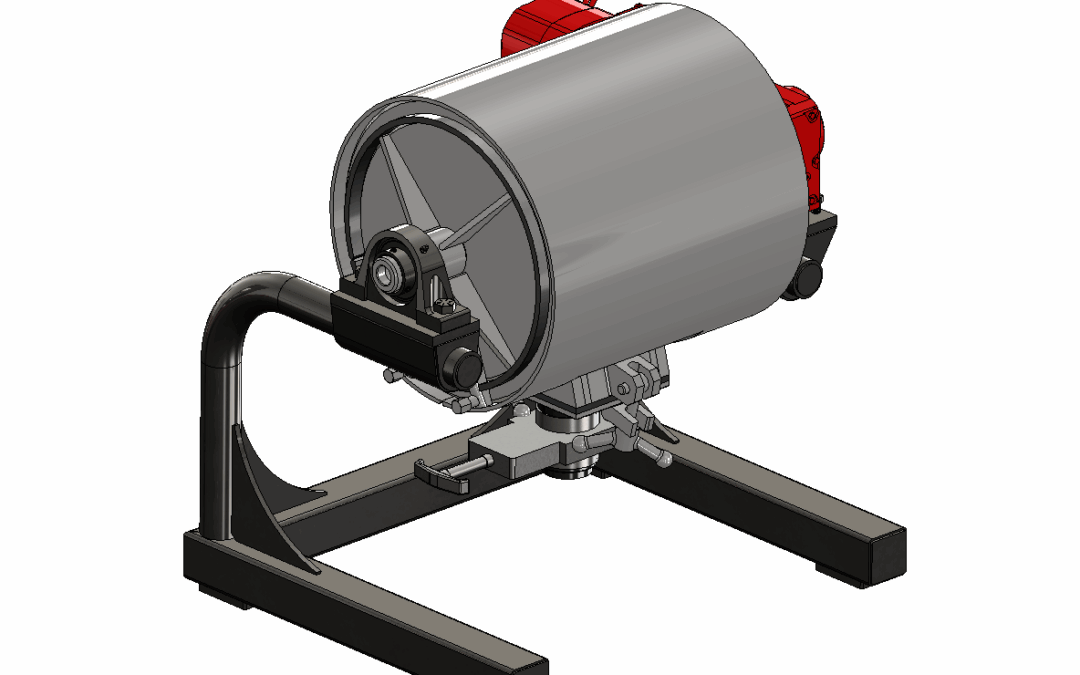

Exploring Paddle Blenders

Paddle blenders, on the other hand, use flat or curved paddles that gently lift, fold, and tumble ingredients instead of slicing through them. This motion provides a low-shear mixing action that’s especially valuable for handling fragile or multi-density materials.

They’re often used when the product mix includes both dry and moist components, or when ingredients must retain their shape during processing.

Key Benefits of Paddle Blenders

-

-

- Gentle Mixing Action: Ideal for delicate ingredients such as nuts, dried fruits, and coated snacks that can be damaged by higher-shear mixers.

- Effective Liquid Incorporation: The paddle’s folding motion allows for even blending of liquids into dry materials, making it ideal for batters, doughs, or slurries.

- Handles Diverse Textures: Accommodates materials with varying particle sizes or densities, maintaining blend integrity.

- Reduced Heat Generation: Minimizes friction and prevents overheating – critical for heat-sensitive ingredients like chocolate, vitamins, or dairy powders.

-

Ribbon vs. Paddle Blenders: Which is Right for Your Application?

Both ribbon and paddle blenders deliver excellent mixing performance, but the best choice depends on your material characteristics and process goals.

| Feature | Ribbon Blender | Paddle Blender |

| Ideal For | Dry, free-flowing powders | Fragile, moist, or sticky materials |

| Mixing Action | Shear, radial and axial | Gentle folding |

| Speed | Faster mix times | Slower mix times |

| Homogeneity | High for similar particles | Better for varied materials |

| Cleanout | Moderate | Easier (open paddles) |

[Ribbon & Paddle Blenders Product Sheet]

Engineering Considerations for Food Manufacturers

When selecting the right blender, it’s not just about the material, it’s about the process requirements. Orbis Machinery works with food processors to design custom-engineered mixers that meet production goals while ensuring safety and repeatability.

Key factors to evaluate include:

-

- Batch size and cycle time

- Viscosity and flow behavior of ingredients

- Cleaning requirements (CIP/SIP compatibility)

- Temperature control and material sensitivity

- Integration with upstream/downstream equipment

By tailoring design parameters, from paddle geometry and motor horsepower to discharge style and surface finish, manufacturers can optimize performance and reduce downtime across their blending operations.

Engineered for Food industry Standards

Orbis blenders are built to order for specific applications across the food, nutraceutical, and chemical sectors. Our engineering team collaborates directly with processors to design equipment that ensures:

- Consistent batch to batch quality

- Sanitary, easy to clean construction

- Energy efficient performance

- Precise, repeatable blending results

Every system is backed by decades of experience in process design and manufacturing, so whether you need a high efficiency ribbon blender or a gentle paddle mixer, Orbis delivers the reliability and quality you expect.

Final Thoughts: Consistency Begins in the Mixer

In food processing, quality control starts long before packaging, it begins at the blending stage. Ribbon and paddle blenders each bring unique advantages to the table, but both share one goal: helping manufacturers deliver consistent, high-quality products efficiently.

Choosing the right blender (and the right partner), can make all the difference in optimizing production and maintaining customer trust.

Ready to upgrade your blending process?

Talk to our engineering team – Contact Us