Introduction

In today’s industrial landscape, sustainability is no longer just a buzzword—it’s a necessity. Industries across the board are under increasing pressure to adopt eco-friendly practices that reduce their environmental impact. This is particularly true for drying processes, where energy consumption and emissions have traditionally been significant. Cone tumble dryers, a staple in many sectors including pharmaceuticals, chemicals, and food processing, are no exception. This article explores newer, eco-friendly drying techniques specifically within cone tumble dryers that enhance efficiency and reduce emissions, positioning Orbis Machinery as a leader in sustainable industrial solutions.

Need for Eco-Friendly Techniques with Cone Tumble Drying

Environmental Challenges in Traditional Cone Tumble Drying

Traditional cone tumble drying techniques have long been associated with high energy consumption and significant emissions. The process typically involves using high temperatures to evaporate moisture from products, which not only consumes large amounts of energy but also releases greenhouse gases and other pollutants into the atmosphere. Additionally, inefficient heat distribution and poor insulation often lead to energy wastage, further exacerbating the environmental footprint.

Regulatory Pressures and Market Demand

With stricter environmental regulations and growing consumer demand for sustainability, industries must innovate and adopt greener technologies. Governments worldwide are implementing policies aimed at reducing industrial emissions and promoting energy efficiency. Customers are also increasingly favoring companies that demonstrate a commitment to sustainability. For these reasons, the shift towards eco-friendly drying techniques is not just beneficial but essential for staying competitive in today’s market.

Overview of New Sustainable Drying Technologies in Cone Tumble Dryers

Enhanced Heat Distribution Systems

A key innovation in making cone tumble dryers more eco-friendly is advanced heat distribution systems. These systems ensure uniform heating throughout the dryer, significantly reducing energy consumption and improving drying efficiency. By optimizing heat distribution, these technologies minimize hotspots and ensure that energy is used effectively, resulting in lower overall consumption and emissions.

Vacuum-Assisted Drying

Vacuum-assisted drying is another promising technology for enhancing the sustainability of cone tumble dryers. By reducing the pressure inside the dryer, vacuum-assisted systems lower the boiling point of water, allowing moisture to evaporate at lower temperatures. This not only speeds up the drying process but also reduces the amount of energy required, leading to lower emissions. The use of vacuum technology also helps preserve the quality of sensitive materials, making it ideal for applications in the pharmaceutical and food industries.

Integration of Renewable Energy Sources

Integrating renewable energy sources such as solar or wind power into cone tumble dryers can further enhance their eco-friendliness. Solar panels can be used to preheat the air or water used in the drying process, reducing reliance on traditional energy sources. Similarly, wind power can generate electricity for the dryer’s operations. These renewable energy integrations not only reduce emissions but also help companies cut energy costs in the long run.

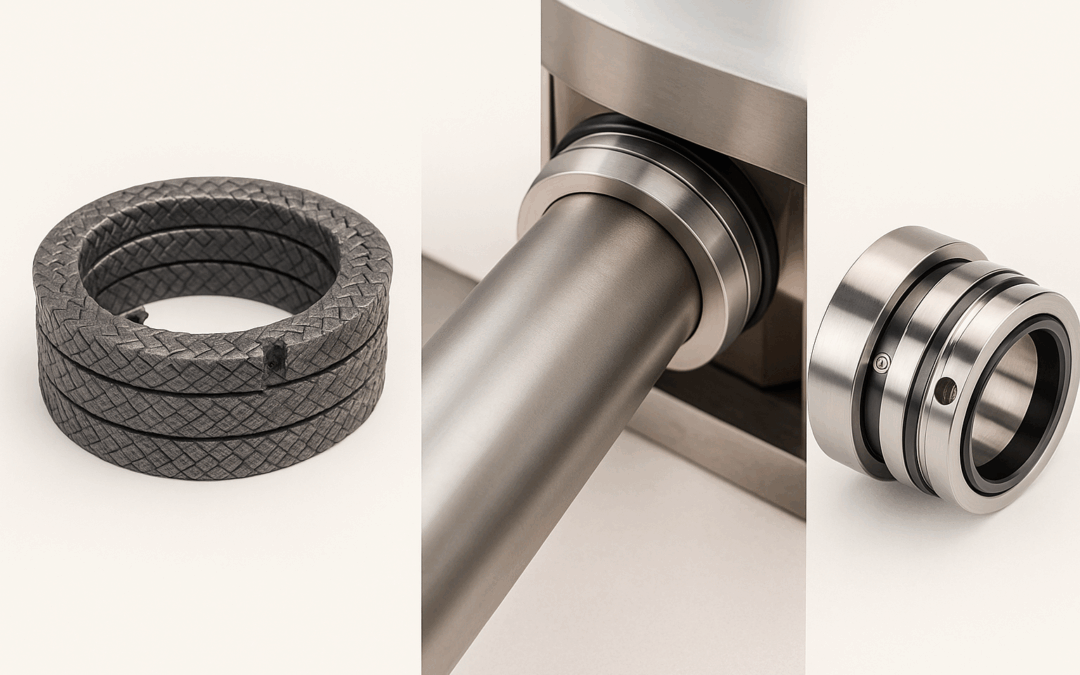

Advanced Insulation and Sealing Techniques

Improved insulation and sealing are critical for minimizing heat loss in cone tumble dryers. Modern insulation materials and advanced sealing techniques ensure that heat remains within the system, reducing the need for additional energy input. By maintaining consistent temperatures and preventing heat from escaping, these improvements contribute to more efficient and eco-friendly drying processes.

Enhancing Efficiency and Reducing Emissions in Cone Tumble Dryers

Energy Recovery Systems

Energy recovery systems are a powerful way to boost the efficiency of your cone tumble drying process. These systems capture waste heat generated during the drying process and reuse it to preheat incoming air or product, thereby reducing overall energy demand. By recycling energy within the system, energy recovery systems can significantly cut emissions and improve the sustainability of the drying process.

Smart Control Systems for Optimized Operations

Smart control systems play a crucial role in optimizing cone tumble drying operations. These systems use sensors and advanced algorithms to monitor and adjust drying parameters in real-time, ensuring optimal conditions for efficiency and energy savings. By precisely controlling factors such as temperature, pressure, and airflow, smart control systems minimize energy use and emissions while maintaining high-quality drying outcomes.

Benefits of Adopting Eco-Friendly Drying Techniques in Cone Tumble Dryers

Environmental Impact

The adoption of eco-friendly drying techniques in cone tumble dryers has a profound positive impact on the environment. Reduced energy consumption leads to lower greenhouse gas emissions, helping companies meet regulatory requirements and contribute to global efforts to combat climate change. Additionally, the use of renewable energy sources and energy recovery systems further minimizes the carbon footprint of drying operations.

Operational Efficiency

Eco-friendly drying techniques not only benefit the environment but also enhance operational efficiency. Advanced heat distribution, vacuum-assisted drying, and smart control systems all contribute to faster, more uniform drying processes. This improved efficiency translates to lower operating costs, as less energy is required to achieve the desired drying outcomes. Companies can achieve significant cost savings while maintaining or even improving product quality.

Compliance and Market Advantage

Adopting sustainable drying technologies positions companies to better comply with environmental regulations and standards. This compliance not only avoids potential fines and penalties but also opens opportunities in markets that prioritize sustainability. Companies that invest in eco-friendly technologies can differentiate themselves from competitors, appealing to environmentally conscious customers and gaining a competitive edge in the market.

Final Thoughts

The shift towards eco-friendly drying techniques in cone tumble dryers is essential for both environmental and operational reasons. Advanced heat distribution systems, vacuum-assisted drying, renewable energy integration, and smart control systems all contribute to more efficient and sustainable drying processes. By adopting these technologies, companies can reduce their environmental impact, enhance operational efficiency, and gain a competitive advantage in the market. At Orbis Machinery, we’re committed to providing innovative and sustainable solutions.