by Orbis Team | Mar 28, 2025 | News

Overcoming Industry Challenges with Adaptive Milling Achieving precision milling in pharmaceuticals, specialty chemicals, and R&D labs is more challenging than ever. Inconsistent particle sizes, excessive reprocessing, and inefficiencies can slow production and...

by Orbis Team | Mar 18, 2025 | Education, News

Why Mixing Matters in Plastics Compounding In plastics compounding, achieving a uniform, high-quality blend is crucial for product performance, durability, and consistency. Poorly mixed materials can lead to defects, inefficient processing, and wasted raw materials....

by Orbis Team | Feb 19, 2025 | Education, News

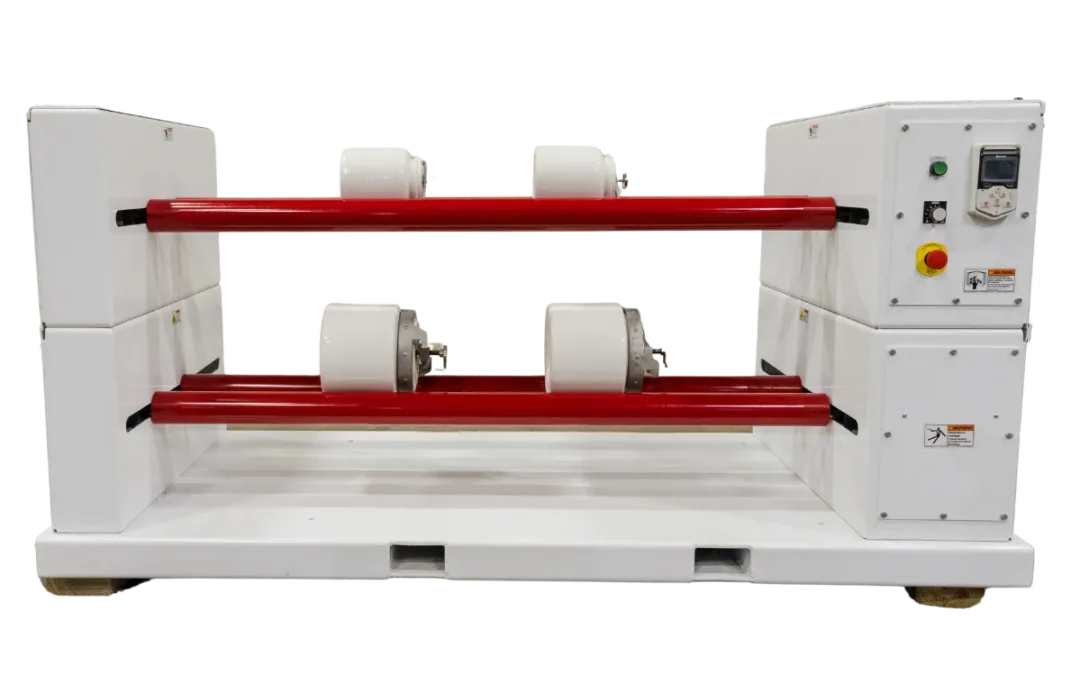

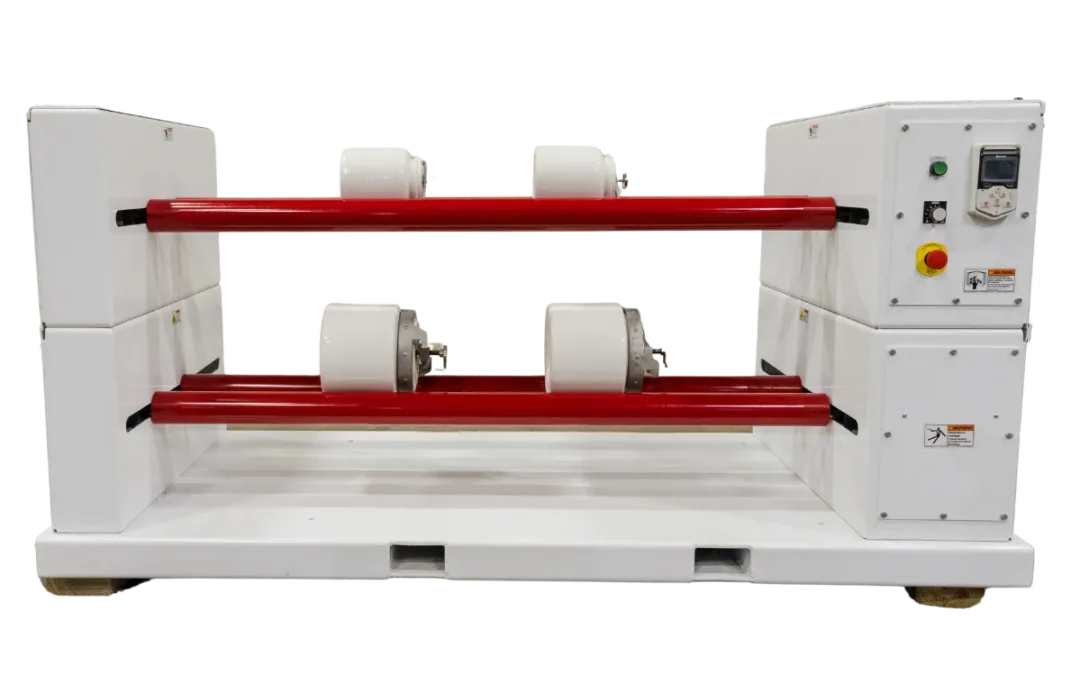

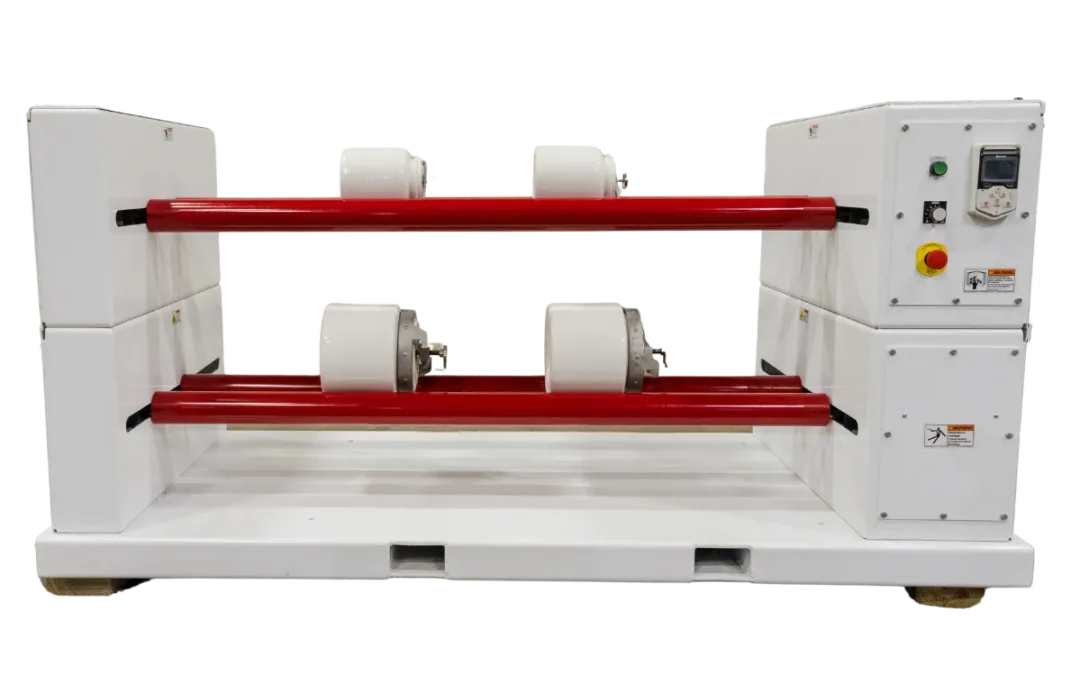

In the advanced ceramics industry, product performance hinges on the uniformity and consistency of raw materials during production. Whether crafting aerospace components, biomedical implants, or electronic insulators, the structural integrity and functional properties...

by Orbis Team | Jan 16, 2025 | Education, News

In industries like food, chemical, or plastics processing, the efficiency and reliability of equipment are crucial to ensuring product quality, meeting regulatory standards, and maintaining operational productivity. However, as processing equipment ages or experiences...

by Orbis Team | Dec 11, 2024 | Education, News

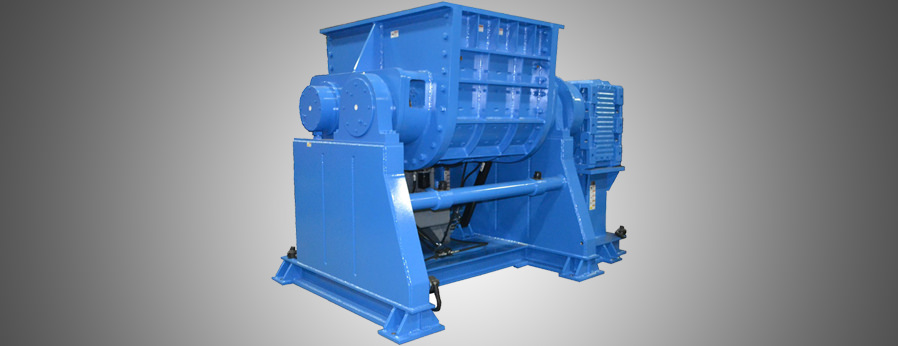

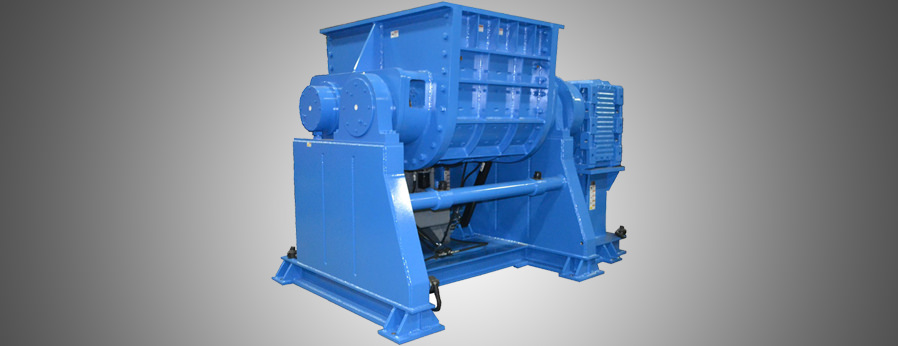

What are Double Arm Mixers and Mixer Extruders? Before delving into the science, it’s essential to understand what Double Arm Mixers and Mixer Extruders are. These mixers are specialized pieces of equipment designed for the efficient mixing of high-viscosity...