Lab Equipment for Testing & Research

Scaled-Down Solutions in R&D, Trials, and Small-Scale Production

Made for Small Scale Success

Orbis Machinery offers a full line of compact mixers, ball mills, blenders, and dryers built to the same high standards as our full-size production equipment. Each unit is engineered for R&D labs, universities, and pilot environments, delivering the durability, control, and repeatability you need to move forward with confidence. Optimized for limited space, small batch sizes, and technical flexibility, our lab equipment provides high-performance processing without sacrificing quality.

Which Lab-Scale Equipment Is Right for You?

Lab Equipment Comparison Table

| Equipment | Best For | Key Features | Common Uses |

|---|---|---|---|

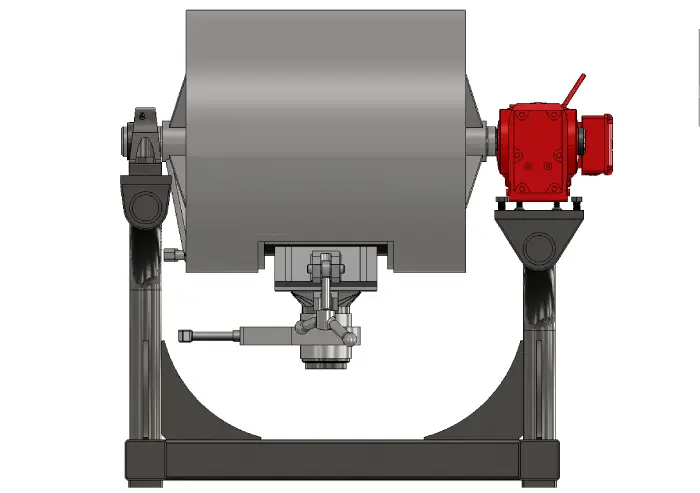

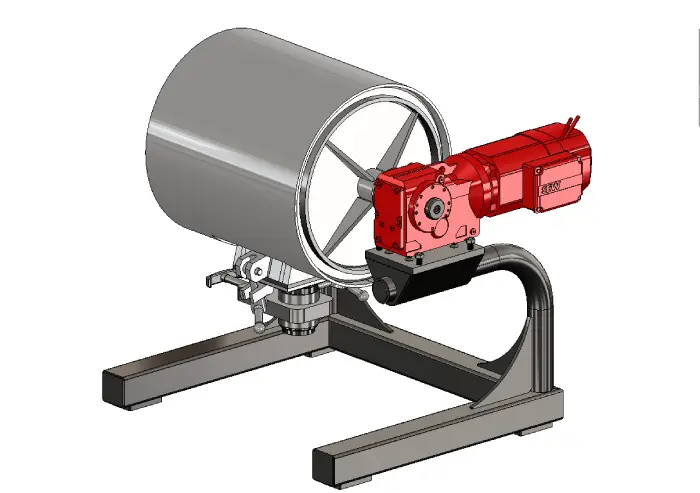

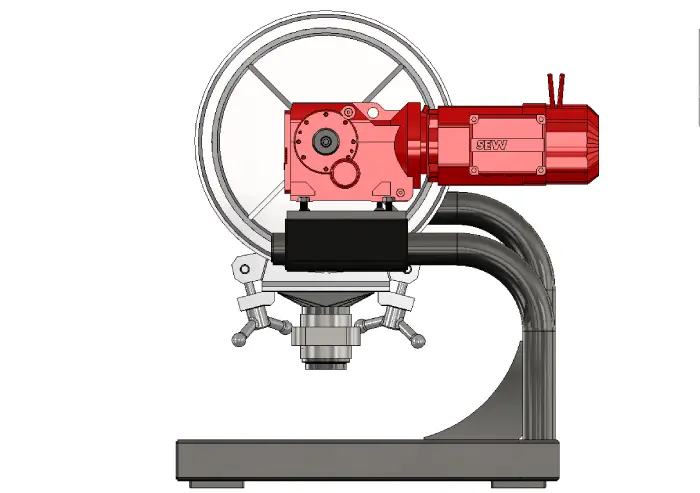

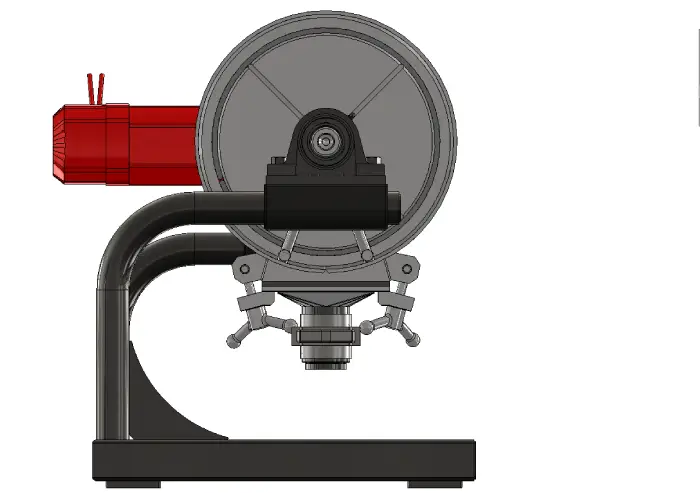

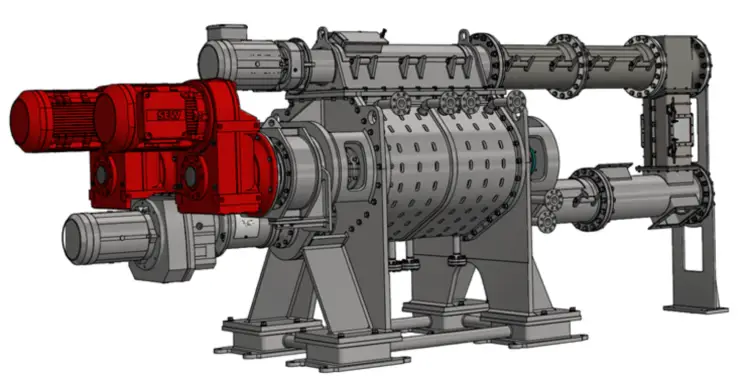

| Lab Ball Mill | Fine grinding | Variable speed, jacket cylinder, multiple media types and styles available, wet or dry grinding. | Ceramics, pigments, coatings, metals from Ore |

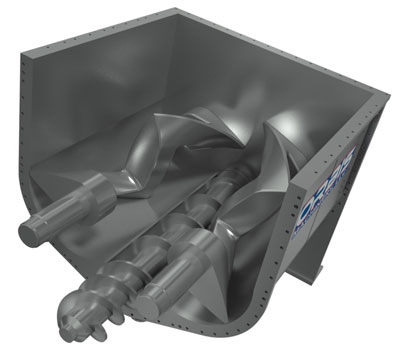

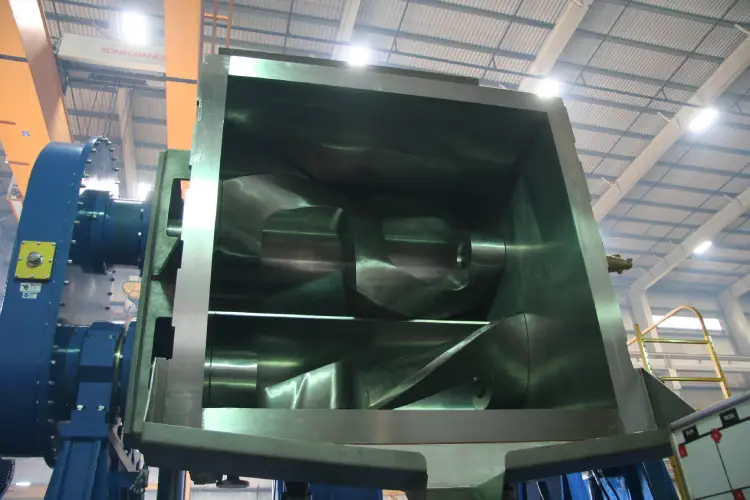

| Sigma Mixer (DKL) | High-viscosity materials | Dual blade, jacketed trough, variable speed | Adhesives, food pastes, composites |

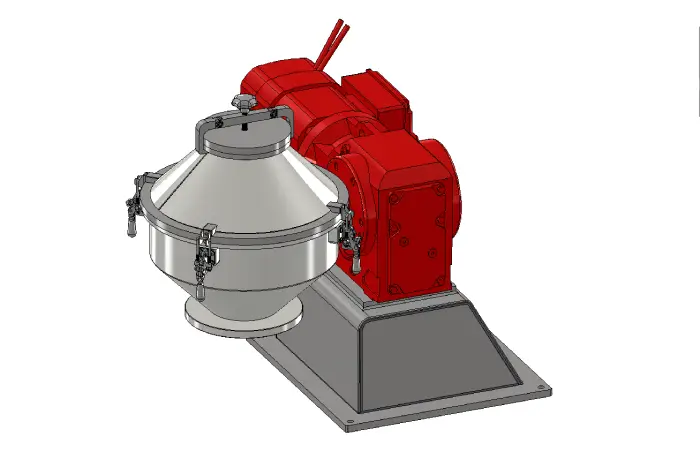

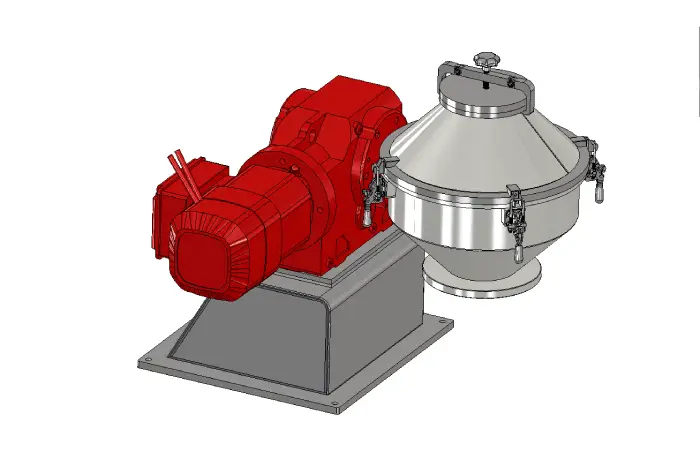

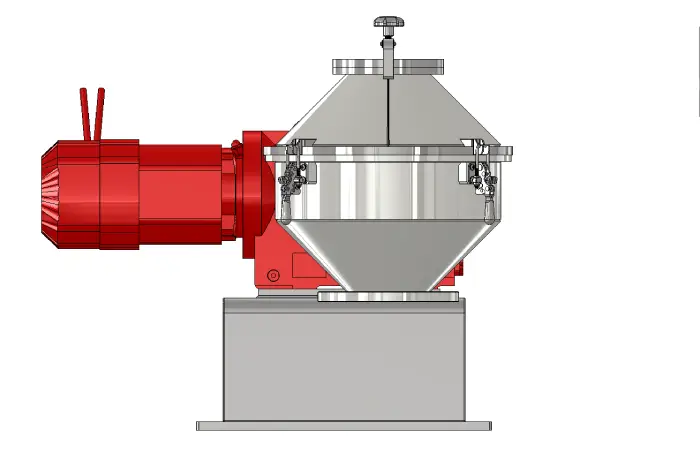

| Tumble Blender | Gentle powder blending | Rotating tumble action, compact size | Nutraceuticals, formulation prep, foods |

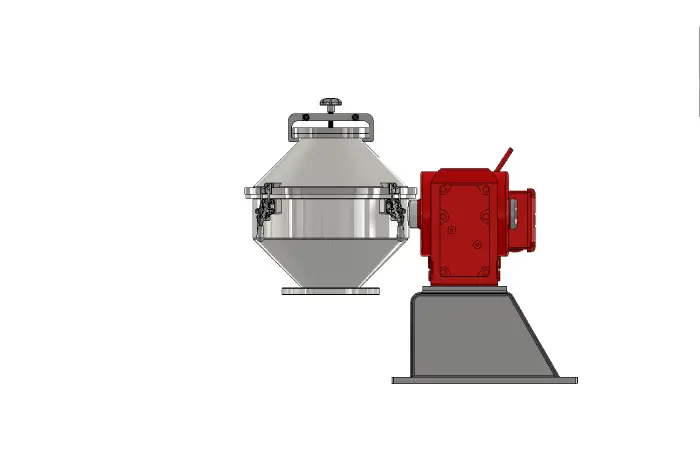

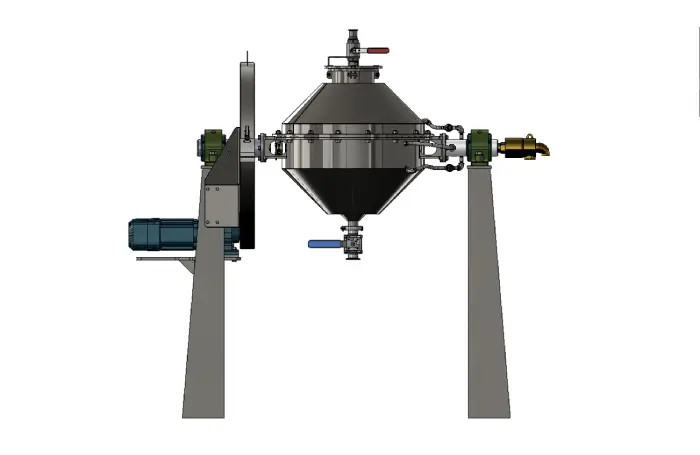

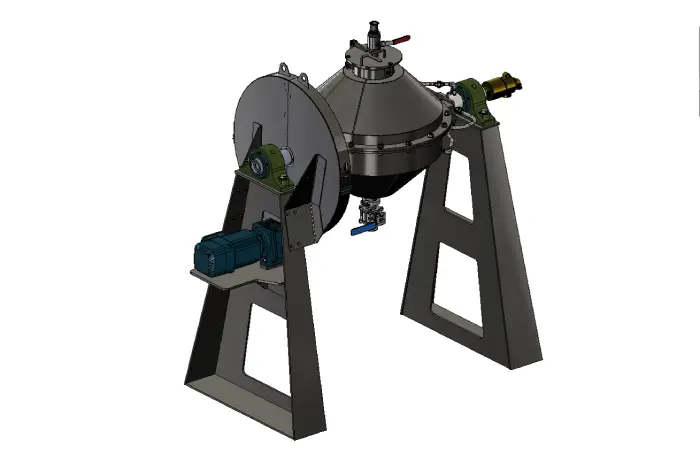

| Cone Tumble Dryer | Controlled drying and blending | Vacuum/convection options, heating jacket | Organics, pharma samples, remove moisture from any semi dry powders |

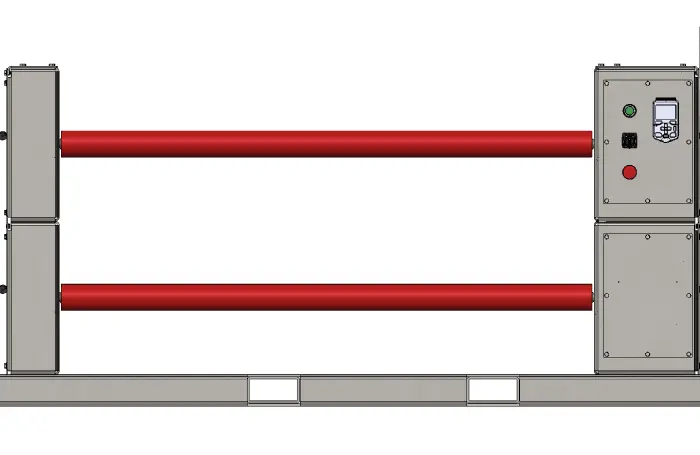

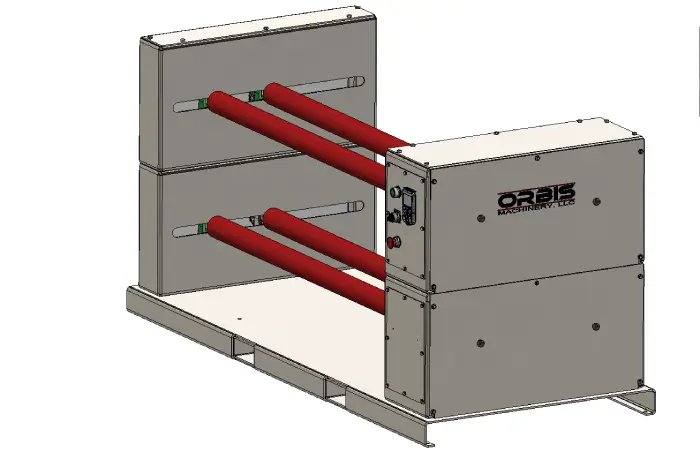

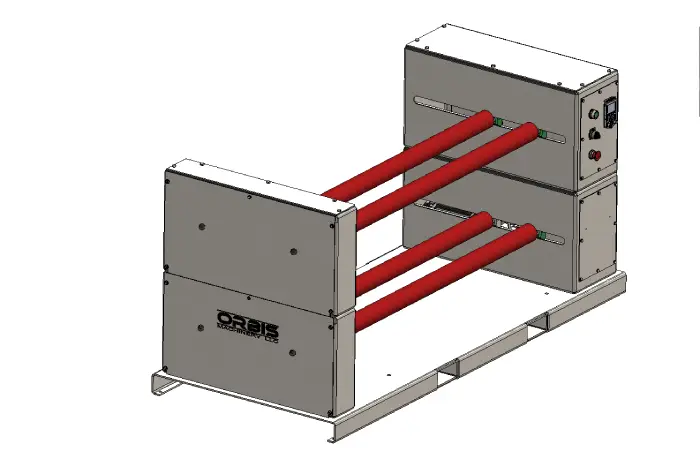

| Adaptive Roller Mill | Particle size reduction | Lab-precision quality control | Ceramics, pigments, coatings, metals from Ore |

Lab Ball Mills (Steel & Lined)

Lab Sigma Mixers (DKL Models)

Lab Blenders – Tumble

Lab Cone Tumble Dryers

Adaptive Roller Mill

Equipment Rentals

Rent lab-scale milling, mixing, blending, and drying equipment to run your testing process or limited production without the upfront capital investment.

How It Works

FAQs

What’s the minimum rental term?

What’s the usual on-site testing time?

Do rentals include support?

Can the rental cost be applied toward purchase?

Is maintenance or cleaning required before return?

Not Sure which equipment is right for you? Submit a CALL REQUEST and we’ll recommend the right equipment for you.