Orbis Machinery, LLC

Mixing | Blending | Drying | Milling

Orbis Machinery, LLC is an independent, owner-managed design, engineering and manufacturing company of process equipment. With over 100 years of combined process and engineering knowledge, Orbis Machinery specializes in double arm mixers, tumble and ribbon blenders, ball mills and rolling mill solutions for the process, medical, and pharmaceutical industries.

Ball Mills

The ball mill is a traditional apparatus for fine grinding. Dating back to the late 1800s, it uses cylindrical containers with journals at its axis that rotate & cascade media along the inside wall.

Tumble Blenders

Blending combines two or more materials into a homogenous mixture. Tumble blending provides gentle mixing action, and we offer cone blenders & v-shape blenders to achieve this.

Paddle & Ribbon Blenders

Paddle & ribbon blenders are useful when working with high concentrations of gums and thickeners. They can be used to add solids that would otherwise clump. It’s a fast & effective way to get consistent texture across multiple batches of products.

Ceramic Ball Mill

Ceramic-lined mills are efficient for reducing or milling hard materials, like minerals, glass, advanced ceramics & semiconductor materials to <1 micron. Used in industries like ceramics, mineral processing & semiconductor fabrication.

Double Arm Mixers

We specialize in custom-designing double arm mixers & mixer extruders for shearing & kneading high viscosity products. We offer 3 types of double arm mixers to provide different advantages according to your process & product needs.

Tumble Dryers

Orbis Machinery’s cone tumble dryer is a superior choice for drying, mixing & cleaning. Featuring a smooth internal finish that prevents cross batch contamination, it can be customized to function with up to 500º F jacket temp & high vacuum.

Lab Roll Mills & Jars

Lab roll mills & jars are used to grind/homogenize both wet and dry materials, primarily for sample prep prior to analysis. They are manufactured for various applications including pharmaceuticals, chemistry, material testing & food analysis.

Need Something Custom?

Our team of experts can work with you to develop a solution tailored precisely to your needs, ensuring the end product fulfills any unique requirements or specific functional requirements.

Our Services

Orbis Machinery process equipment machine services include sales and engineering of new equipment, rebuilding existing client machinery, reverse engineering and field service for installation of equipment.

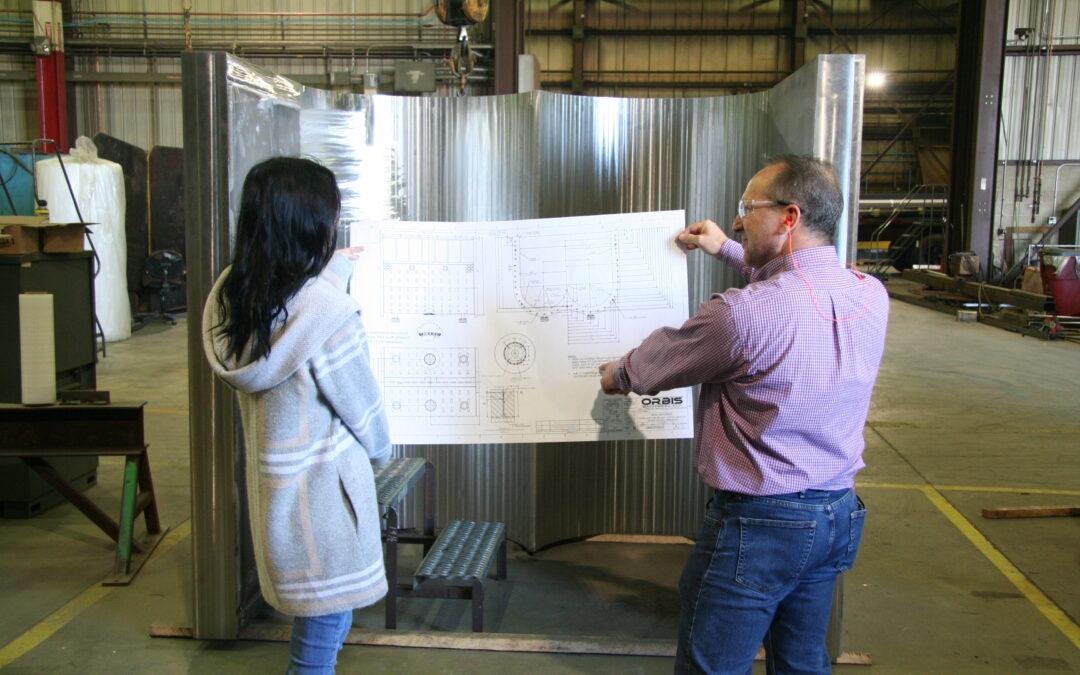

Engineering

Installation

Fabrication & Machining

Rebuilding

Mill Relining

Markets

We Serve

We serve a wide range of industries, including food, confection, silicone, rubber, carbon, chemical, nutraceutical, composite and plastics. Our innovative products are designed to meet the specific needs of each industry and provide top-tier performance no matter the complexity of the processing project. With an experienced team of engineers and processing specialists on staff available to provide advice and service with technical assistance any time you need it.